|

|

|

报告导航:研究报告—

TMT产业—消费电子

|

|

2014-2016年全球和中国锂电池隔膜行业研究报告 |

|

字数:3.4万 |

页数:132 |

图表数:135 |

|

中文电子版:8500元 |

中文纸版:4250元 |

中文(电子+纸)版:9000元 |

|

英文电子版:2400美元 |

英文纸版:2600美元 |

英文(电子+纸)版:2700美元 |

|

编号:YS001

|

发布日期:2014-06 |

附件:下载 |

|

|

|

锂电池电芯主要由正极材料、负极材料、电解液和隔膜组成,其中锂电池隔膜是锂电池材料中技术壁垒最高的一种高附加值材料,约占电池成本的15-20%,其主要作用是将电池正、负极分隔开,防止两极接触造成短路。

2013年,全球以及中国锂电池隔膜主要呈现以下几个特点:

第一,全球产能大幅扩张,价格持续下跌。

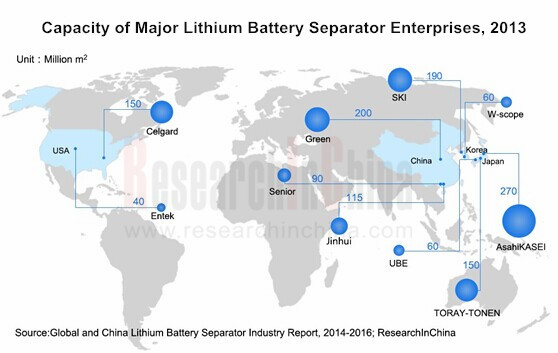

据水清木华研究中心统计,截至2013年,全球(除中国外)主流的隔膜供应商投产产能10.18亿m2。其中湿法占据主导,产能达8.48亿m2;干法产能1.7亿m2,主要厂商是美国Celgard和日本宇部兴产,在建干法产能1.8亿m2。

全球锂电池隔膜出货量由2008年的2.73亿m2增长至2013年的8.43亿m2,全球整体产能也由2008年的3.62亿m2增长至2013年的19亿m2,产能扩大速度远大于需求增长。2013年全球产能利用率也随之下降至44%。

在隔膜市场巨大的市场需求拉动下,全球产能还将持续投放,预计未来全球锂电池隔膜市场将呈现量增价跌的市场特征,隔膜均价将从2013年的1.73美元/ m2下跌至2016年的1.48美元/ m2。

第二,锂电池隔膜市场集中度持续下降。

随着中国锂电池隔膜产能大量投产,全球隔膜市场集中度出现下降。2013年日本旭化成、美国Celgard、韩国SKI、日本东丽东燃等四家企业占据了全球56.8%的市场份额,市场集中度相较2008年大幅下降。2008年全球前四大企业分别为日本旭化成、美国Celgard、日本东丽东燃、日本宇部兴产,占据82.8%市场份额。

2013年中国国产隔膜出货量达2.65亿m2,同比增长61%,占全球出货量比重由2010年的17%上升至2013年的31%,国产化率由2010年的28%上升至2013年的52%。2013年,国内最大的三家隔膜供应商新乡格瑞恩、星源材质和金辉高科市场份额占比达52.4%。

第三,高性能隔膜将成为未来锂电池隔膜市场的主要需求增长点。

2013年全球锂电池隔膜出货量达8.43亿m2,同比增长33.2%,2007-2013年复合增长率达22.6%。由于电动汽车、储能设备等对动力锂电池强劲需求,预计到2016年,全球锂电池隔膜需求将达19.9亿m2,2013-2016年复合增长率高达33%。

普通锂电池隔膜,2013年全球用于3C电子产品的普通隔膜出货量为6.33亿m2,到2016年普通隔膜出货量将达11.35亿m2,2013-2016年复合增长率仅为11%,这是由于从2014年开始,全球笔记本电脑、智能手机、平板电脑等数码产品需求将明显放缓。

高性能锂电池隔膜,2013年全球用于电动汽车、储能装置的高性能隔膜出货量2.1亿m2,需求占比达25%。到2016年,全球高性能隔膜出货量将达11.35亿m2,需求占比达57%,2013-2016年复合增长率达75%。高性能隔膜将成为未来锂电池隔膜市场的主要需求增长点。

水清木华研究中心《2014-2016年全球和中国锂电池隔膜行业研究报告》着重研究了以下内容:

锂电池隔膜生产制备工艺,关键技术性能,技术发展方向; 锂电池隔膜生产制备工艺,关键技术性能,技术发展方向;

全球及中国锂电池隔膜行业出货量、进口量、市场规模、价格等; 全球及中国锂电池隔膜行业出货量、进口量、市场规模、价格等;

全球及中国锂电池隔膜企业市场份额、生产工艺、产能、供应配套关系等; 全球及中国锂电池隔膜企业市场份额、生产工艺、产能、供应配套关系等;

全球及中国普通锂电池和动力电池出货量、市场规模、电芯厂商分析等; 全球及中国普通锂电池和动力电池出货量、市场规模、电芯厂商分析等;

中国10家锂电池隔膜厂商经营、技术、市场及产销动态; 中国10家锂电池隔膜厂商经营、技术、市场及产销动态;

全球9家锂电池隔膜厂商经营、技术、市场及产销动态。 全球9家锂电池隔膜厂商经营、技术、市场及产销动态。

The lithium battery cell is composed of cathode material, anode material, electrolyte and separator, of which, lithium battery separator as a high value-added material with the highest technical barrier among lithium battery materials accounts for about 15-20% of the battery cost. The main role of the separator is to separate the positive and negative electrodes of the lithium-ion battery, thus preventing two neighboring contacts from a short circuit.

In 2013, the global and Chinese lithium battery separator mainly presented the following characteristics:

First, the global capacity was expanded by a large margin, and prices continued to fall.

According to ResearchInChina, the global mainstream suppliers of separator (other than China) had put 1.018-billion-m2 capacity into production as of 2013, of which, the wet process held a dominant position by attaining 848 million m2; the dry process contributed 170 million m2, which came mainly from U.S.-based Celgard and Japan-based UBE Industries, with 180-million-m2 dry process capacity under construction.

The global shipment of lithium battery separator increased from 273 million m2 in 2008 to 843 million m2 in 2013, so did the overall capacity from 362 million m2 to 1.9 billion m2, the capacity expansion grew much faster than demand. The global capacity utilization then fell to 44% in 2013.

Boosted by the huge market demand for separator, the global capacity will continue to be released. It is expected that the global lithium battery separator market will be featured with quantity increases and price collapses, with the average price falling from USD1.73 / m2 in 2013 to USD1.48 / m2 in 2016.

Second, the lithium battery separator market concentration continued to decline.

As the Chinese lithium battery separator capacity was put into production in large quantities, the global separator market concentration suffered decline. In 2013, Japan-based Asahi Kasei, U.S.-based Celgard, South Korea-based SKI and Japan-based Toray Tonen occupied a 56.8% share of the global market, showing a sharp decline as opposed to the market concentration in 2008, when Asahi Kasei, Celgard, Toray Tonen and UBE Industries as the top four companies accounted for 82.8%.

In 2013, China’s domestic separator shipment reached 265 million m2, showing a year-on-year increase of 61%, the proportion (in global shipment) rose from 17% in 2010 to 31% in 2013, so did the localization rate from 28% to 52%. The same year, the three biggest suppliers of separator in China - Xinxiang Zhongke Science and Technology (GREEN) Co., Ltd, Shenzhen Senior Technology Material Co., LTD and Foshan Jinhui Hi-tech Optoelectronic Material Co., Ltd hit 52.4% market share.

Third, the high-performance separator will become the main demand growth point for the future lithium battery separator market.

In 2013, the global shipment of lithium battery separator attained 843 million m2, up 33.2% YoY; the compound growth rate was 22.6% in 2007-2013. In view of the strong demand from electric vehicles, energy storage devices, etc. for power lithium battery, the global demand for lithium battery separator will come to 1.99 billion m2 in 2016, at a compound growth rate as high as 33% in 2013-2016.

The global shipment of ordinary lithium battery separator used for 3C electronic products reached 633 million m2 in 2013, expected to grow at a compound rate of only 11% in 2013-2016, to 1.135 billion m2 by 2016. This is due to the slowdown in global demand for notebook, smartphone, tablet PC and other digital products since 2014.

In 2013, the global shipment of high-performance separator used for electric vehicles and energy storage devices realized 210 million m2, accounting for 25% of the demand; by 2016, the shipment will hit 1.135 billion m2 (at a compound growth rate of 75% in 2013-2016), with a demand proportion of 57%. Thus, the high-performance separator will become the main demand growth point for the lithium battery separator market in the future.

Global and China Lithium Battery Separator Industry Report, 2014-2016 by ResearchInChina mainly covers the followings:

Production preparation process, key technical performance and technology development direction of lithium battery separator; Production preparation process, key technical performance and technology development direction of lithium battery separator;

Shipment, import volume, market size, price, etc. of the global and Chinese lithium battery separator industry; Shipment, import volume, market size, price, etc. of the global and Chinese lithium battery separator industry;

Market share, manufacturing technique, capacity, supply relationship, etc. of global and Chinese lithium battery separator companies; Market share, manufacturing technique, capacity, supply relationship, etc. of global and Chinese lithium battery separator companies;

Shipment, market size, cell vendors of global and Chinese ordinary lithium batteries and power batteries. Shipment, market size, cell vendors of global and Chinese ordinary lithium batteries and power batteries.

Operation, technology, market, production & marketing of ten lithium battery separator companies in China; Operation, technology, market, production & marketing of ten lithium battery separator companies in China;

Operation, technology, market, production & marketing of nine lithium battery separator companies in the world. Operation, technology, market, production & marketing of nine lithium battery separator companies in the world.

第一章 锂电池隔膜简介

1.1 锂电池隔膜特性和用途

1.2 锂电池隔膜分类

第二章 锂电池隔膜生产制备和技术性能

2.1 基体材料

2.1.1聚烯烃

2.1.2无纺布

2.1.3陶瓷涂层

2.2生产工艺

2.2.1 湿法

2.2.2 干法

2.2.3 生产工艺对比

2.3关键技术指标

2.3.1孔隙率

2.3.2透气度

2.3.3吸液率

2.3.4孔径大小及分布

2.3.5力学性能

2.3.6自动关断保护性能

2.3.7热收缩率

2.3.8关键技术指标对比

2.4技术发展方向

第三章 全球锂电池隔膜行业分析

3.1 全球锂电池隔膜市场

3.1.1市场需求

3.1.2市场规模

3.1.3产品价格

3.2 全球锂电池隔膜企业

3.2.1市场份额

3.2.2工艺和产能

3.2.3供应配套关系

第四章 中国锂电池隔膜行业分析

4.1中国锂电池隔膜市场

4.1.1 市场需求

4.1.2 国产/进口隔膜

4.1.3 市场规模

4.1.4 产品价格

4.2中国锂电池隔膜企业

4.2.1市场份额

4.2.2工艺和产能

4.2.3供应配套关系

第五章 全球及中国锂电池行业分析

5.1全球锂电池需求

5.1.1 普通3C锂电池需求

5.1.2动力锂电池需求

5.1.3锂电池出货量

5.1.4锂电池市场规模

5.2中国锂电池需求

5.2.1动力锂电池需求

5.2.2锂电池出货量

5.2.3锂电池市场规模

5.3主要锂电池厂商

5.3.1市场份额

5.3.2动力电池厂商

第六章 全球锂离子电池隔膜厂商

6.1 AsahiKASEI(旭化成株式会社)

6.1.1公司简介

6.1.2技术工艺

6.1.3在华布局

6.1.4生产和销售网络

6.1.5产量产能

6.2 Celgard

6.2.1公司简介

6.2.2技术工艺

6.2.3在华布局

6.2.4生产和销售网络

6.2.5产量产能

6.2.6投资计划

6.3 Toray Tonen(东丽东燃)

6.4 UBE(宇部兴产)

6.4.1公司简介

6.4.2技术工艺

6.4.3生产和销售网络

6.4.4产量产能

6.5 SKI(SK创新)

6.5.1公司简介

6.5.2技术工艺

6.5.3产量产能

6.5.4客户分析

6.6 Entek (恩泰克)

6.7 Mitsubishi Chemical(三菱化学)

6.7.1公司简介

6.7.2术工艺

6.8 Sumitomo Chemical(住友化学)

6.9 Evonik Industries(赢创工业集团)

6.10 W-Scope

6.10.1公司简介

6.10.2经营情况

6.10.3毛利率分析

6.10.4产量产能

第七章 中国锂离子电池隔膜厂商

7.1新乡市中科科技(格瑞恩新能源)有限公司

7.1.1公司简介

7.1.2技术工艺

7.1.3产量产能

7.2深圳市星源材质科技股份有限公司

7.2.1 公司简介

7.2.2 技术工艺

7.2.3 产量产能

7.3佛山市金辉高科光电材料有限公司

7.3.1 公司简介

7.3.2 经营情况

7.3.3技术工艺

7.3.4产量产能

7.4沧州明珠塑料股份有限公司

7.4.1公司简介

7.4.2经营情况

7.4.3 毛利率分析

7.4.4 技术工艺

7.4.5 产量产能

7.4.6 客户分析

7.4.7 预测与展望

7.5江西先材纳米纤维科技有限公司

7.5.1公司简介

7.5.2经营情况

7.5.3技术工艺

7.5.4投资计划

7.6中材科技股份有限公司

7.7 浙江大东南股份有限公司

7.8 江苏九九久科技股份有限公司

7.9南通天丰电子新材料有限公司

1 Introduction to Lithium Battery Separator

1.1 Properties and Application

1.2 Classification

2 Lithium Battery Separator Production Preparation and Technical Performance

2.1 Base Material

2.1.1 Polyolefin

2.1.2 Non-woven Fabrics

2.1.3 Ceramic Coating

2.2 Production Technique

2.2.1 Wet Process

2.2.2 Dry Process

2.2.3 Comparison of Production Techniques

2.3 Key Technical Indices

2.3.1 Porosity

2.3.2 Air Permeability

2.3.3 Electrolyte Uptake

2.3.4 Aperture Size and Distribution

2.3.5 Mechanical Property

2.3.6 Automatic Shutdown Protection Performance

2.3.7 Thermal Shrinkage

2.3.8 Comparison of Key Technical Indices

2.4 Development Orientation of Technology

3 Global Lithium Battery Separator Industry

3.1 Global Lithium Battery Separator Market

3.1.1 Market Demand

3.1.2 Market Size

3.1.3 Product Price

3.2 Global Lithium Battery Separator Companies

3.2.1 Market Share

3.2.2 Technique and Capacity

3.2.3 Supply Relationship

4 China Lithium Battery Separator Industry

4.1 China Lithium Battery Separator Market

4.1.1 Market Demand

4.1.2 Homemade/Imported Separator

4.1.3 Market Size

4.1.4 Product Price

4.2 Chinese Lithium Battery Separator Companies

4.2.1 Market Share

4.2.2 Technique and Capacity

4.2.3 Supply Relationship

5 Global and China Lithium Battery Industry

5.1 Global Demand for Lithium Battery

5.1.1 Demand for Ordinary 3C Lithium Battery

5.1.2 Demand for Power Lithium Battery

5.1.3 Lithium Battery Shipment

5.1.4 Lithium Battery Market Size

5.2 China’s Demand for Lithium Battery

5.2.1 Demand for Power Lithium Battery

5.2.2 Lithium Battery Shipment

5.2.3 Lithium Battery Market Size

5.3 Major Lithium Battery Manufacturers

5.3.1 Market Share

5.3.2 Power Battery Manufacturers

6 Global Li-ion Battery Separator Manufacturers

6.1 Asahi Kasei

6.1.1 Profile

6.1.2 Technology & Technique

6.1.3 Layout in China

6.1.4 Production and Marketing Network

6.1.5 Capacity and Output

6.2 Celgard

6.2.1 Profile

6.2.2 Technology & Technique

6.2.3 Layout in China

6.2.4 Production and Marketing Network

6.2.5 Capacity and Output

6.2.6 Investment Plan

6.3 Toray Tonen

6.4 UBE

6.4.1 Profile

6.4.2 Technology & Technique

6.4.3 Production and Marketing Network

6.4.4 Capacity and Output

6.5 SKI

6.5.1 Profile

6.5.2 Technology & Technique

6.5.3 Capacity and Output

6.5.4 Customers

6.6 Entek

6.7 Mitsubishi Chemical

6.7.1 Profile

6.7.2 Technology & Technique

6.8 Sumitomo Chemical

6.9 Evonik Industries

6.10 W-Scope

6.10.1 Profile

6.10.2 Operation

6.10.3 Gross Margin

6.10.4 Capacity and Output

7 Chinese Li-ion Battery Separator Manufacturers

7.1 Xinxiang Zhongke Science and Technology (GREEN) Co., Ltd

7.1.1 Profile

7.1.2 Technology & Technique

7.1.3 Capacity and Output

7.2 Shenzhen Senior Technology Material Co., Ltd

7.2.1 Profile

7.2.2 Technology & Technique

7.2.3 Capacity and Output

7.3 Foshan Jinhui Hi-tech Optoelectronic Material Co., Ltd

7.3.1 Profile

7.3.2 Operation

7.3.3 Technology & Technique

7.3.4 Capacity and Output

7.4 Cangzhou Mingzhu Plastic Co., Ltd

7.4.1 Profile

7.4.2 Operation

7.4.3 Gross Margin

7.4.4 Technology & Technique

7.4.5 Capacity and Output

7.4.6 Customers

7.4.7 Forecast and Outlook

7.5 Jiangxi Xian Cai Nanofibers Technology Co., Ltd

7.5.1 Profile

7.5.2 Operation

7.5.3 Technology & Technique

7.5.4 Investment Plan

7.6 Sinoma Science & Technology Co., Ltd

7.7 Zhejiang Great Southeast Co., Ltd

7.8 Jiangsu Jiujiujiu Technology Co., Ltd

7.9 Nantong Tianfeng New Electronic Materials Co., Ltd

图:锂离子电池工作原理图

表:聚烯烃隔膜结构与特点

表:无纺布隔膜技术特点和代表公司

图:陶瓷涂层隔膜耐高温性能提升

图:湿法PE隔膜显微图

图:干法PP隔膜显微图

表:不同生产工艺的锂电池隔膜结构与特点

表:中国湿法和干法工艺投资成本对比

表:不同隔膜透气度对比

图:不同制备方法的隔膜孔径分布图

表:不同隔膜拉伸强度对比

表:不同隔膜穿刺强度对比

表:不同隔膜自动关断性能对比

表:不同隔膜热收缩率对比

表:不同基体材料隔膜关键技术指标

表:常见电子产品、汽车锂电池隔膜消耗量

图:2007-2016年全球锂电池隔膜出货量

图:2008-2016年全球普通和高性能锂电池隔膜出货量

图:2008-2016年全球锂电池隔膜市场规模

图:2008-2016年全球锂电池隔膜均价

图:2013年全球锂电池隔膜企业市场份额(按出货量)

图:2008年全球锂电池隔膜企业市场份额(按出货量)

表:2013年底国际锂电池隔膜厂商工艺及产能

表:2013年国际锂电池隔膜厂商供应配套关系

表:2013年国际动力锂电池隔膜厂商供应配套关系

图:2009-2016年中国锂电池隔膜出货量

图:2009-2016年中国普通和高性能锂电池隔膜出货量

图:2010-2016年中国高性能锂电池隔膜出货量占全球比重

图:2009-2016年中国国产锂电池隔膜出货量

图:2009-2016年中国国产锂电池隔膜出货量占全球比重

图:2010-2016年中国国产、进口锂电池隔膜数量和进口依赖度

图:2009-2016年中国聚烯烃锂电池隔膜进口数量和金额

图:2013年中国聚烯烃锂电池隔膜进口来源地

图:2009-2016年中国锂电池隔膜市场规模

图:2009-2016年中国国产、进口锂电池隔膜市场规模

图:2009-2016年中国国产和进口隔膜均价

图:2013年中国国产锂电池隔膜企业市场份额(按出货量)

图:2013年中国国产锂电池隔膜企业市场份额(按销售金额)

表:2013年底中国国产锂电池隔膜厂商工艺及产能

表:2013年中国国产锂电池隔膜厂商供应配套关系

图:锂离子电池应用领域

图:2012-2016年全球笔记本、平板电脑、手机出货量

图:2012-2016年全球笔记本、平板电脑、手机锂电池出货量

图:2008-2016年全球电动汽车销量

表:全球主要电动汽车电池容量及续航能力

图:2008-2016年全球电动汽车单车电池容量

图:2008-2016年全球电动汽车动力电池需求

图:2008-2016年全球锂电池出货量

图:2008-2016年全球锂电池出货量

图:2012-2016年全球锂电池需求结构占比

图:2008-2016年全球锂电池分需求出货量

图:2008-2016年全球锂电池产业规模

图:2008-2016年中国电动汽车销量

图:2008-2016年中国电动汽车销量占全球比重

图:2008-2016年中国锂电池出货量

图:2008-2016年中国锂电池出货单元占全球比重

图:2008-2016年中国锂电池产业规模

图:2008-2016年中国锂电池产业规模占全球比重

图:2010-2016年中国动力锂电池产业规模与占比

图:2012-2013年中国、日本、韩国锂电池出货量占比

图:2013年全球小型锂电池企业市场份额

图:2013年全球动力锂电池企业市场份额

表:全球合资动力锂电池供应商

表:2013年中国动力锂电池企业电池技术和销售额

图:2013/14财年旭化成主营业务收入构成

图:旭化成电池隔膜显微图

图:旭化成锂电池隔膜(亚洲除日本)生产基地

表:日本旭化成(中国)管理机构

图:旭化成锂电池隔膜(日本)生产基地

表:2004-2013年旭化成电池隔膜产能投放规模

表:旭化成电池隔膜市场部门联系方式

图:2008-2013年旭化成电池隔膜产量、产能与产能利用率

表:Celgard全球分支机构

表:Celgard电池隔膜技术参数

表:Celgard(中国)管理机构

图:Celgard锂电池隔膜全球生产基地和销售网络

图:2008-2013年Celgard电池隔膜产量、产能与产能利用率

表:Celgard电池隔膜投资计划

图:东丽东燃股权结构图

图:2008-2013年Toray Tonen电池隔膜产量、产能与产能利用率

图:2008/09-2013/14财年宇部兴产经营业绩

图:2013/14财年宇部兴产主营业务收入构成

表:宇部兴产电池隔膜业务部门联系方式

图:宇部兴产电池隔膜(日本)生产基地

图:2008-2013年宇部兴产电池隔膜产量、产能与产能利用率

图:SKI旗下主要子公司

图:2009-2013年SKI电池隔膜产量、产能与产能利用率

表:Entek电池隔膜业务部门联系方式

表:Entek电池隔膜技术参数

表:2013/14财年三菱化学主营业务收入构成

图:三菱化学全球分支机构

图:三菱化学锂电池隔膜生产工艺

表:2013/14财年住友化学主营业务收入构成

图:住友化学锂电池隔膜技术性能

图:住友化学电子材料部门全球分支机构

图:2010-2014年W-Scope经营业绩

图:2013年W-Scope电池隔膜销售区域

图:2009-2013年W-Scope电池隔膜毛利率

图:2009-2013年W-Scope电池隔膜产量、产能与产能利用率

表:新乡格瑞恩GRE-P系列隔膜技术参数

表:新乡格瑞恩GRE-T系列隔膜技术参数

表:新乡格瑞恩GRE-H系列隔膜技术参数

图:2007-2013年新乡格瑞恩锂电池隔膜产量、产能及产能利用率

图:星源材质主要锂电池电芯客户

图:星源材质全球销售网络

图:星源材质干法和湿法锂电池隔膜显微图

图:星源材质特种锂电池隔膜显微图

表:星源材质锂电池隔膜投资及扩产计划

图:2007-2013年星源材质锂电池隔膜产量、产能及产能利用率

图:金辉高科股权结构变动

表:2009-2013年金辉高科经营业绩

表:金辉高科普通型锂电池隔膜技术参数

表:金辉高科加强型锂电池隔膜技术参数

表:金辉高科锂电池隔膜投资及扩产计划

图:2008-2013年金辉高科锂电池隔膜产量、产能及产能利用率

图:2009-2014Q1年沧州明珠经营业绩

图:2007-2013年沧州明珠主营业务收入构成

图:2007-2013年沧州明珠主营业务毛利率

表:沧州明珠锂电池隔膜技术参数

表:2012-2013年沧州明珠锂电池隔膜产销与营收

表:沧州明珠锂电池隔膜投资及扩产计划

图:2012-2016年沧州明珠锂电池隔膜产量、产能与产能利用率

图:2013-2014.3比亚迪电动汽车销量

表:比亚迪电动汽车锂电池容量及隔膜需求

图:2012-2016年比亚迪动力锂电池与隔膜需求

图:2012-2016年沧州明珠锂电池隔膜营收和净利润

表:江西先材股权结构

表:2012-2013年江西先材经营情况

表:江西先材聚酰亚胺(PI)纳米电池隔膜技术参数

表:江西先材聚酰亚胺(PI)纳米电池隔膜投资计划

表:中材科技锂电池隔膜投资计划

表:大东南锂电池隔膜投资计划

表:九九九锂电池隔膜投资计划

表:南通天丰锂电池隔膜技术参数

表:锂离子电池发展趋势

Working Principles of Li-ion Battery

Polyolefin Separator Structure and Features

Characteristics of Non-woven Fabric Separator Technology and Typical Companies

Improvement of High Temperature Resistance of Ceramic Coated Separator

Micrograph of Wet Process PE Separator

Micrograph of Dry Process PP Separator

Structure and Features of Lithium Battery Separator with Varied Production Techniques

Comparison: Investment Costs of Wet Process and Dry Process in China

Comparison: Air Permeability of Different Separators

Aperture Distribution of Separators with Different Preparation Methods

Comparison: Tensile Strength of Different Separators

Comparison: Puncture Strength of Different Separators

Comparison: Automatic Shutdown Performance of Different Separators

Comparison: Thermal Shrinkage of Different Separators

Key Technical Indices of Separators with Different Base Materials

Common Electronics and Automobiles’ Consumption of Lithium Battery Separator

Global Shipment of Lithium Battery Separator, 2007-2016E

Global Shipment of Ordinary and High-performance Lithium Battery Separator, 2008-2016E

Global Lithium Battery Separator Market Size, 2008-2016E

Average Price of Global Lithium Battery Separator, 2008-2016E

Market Share of World’s Lithium Battery Separator Enterprises by Shipment, 2013

Market Share of World’s Lithium Battery Separator Enterprises by Shipment, 2008

Techniques and Production Capacities of International Lithium Battery Separator Manufacturers at the End of 2013

Supply Relationship of International Lithium Battery Separator Manufacturers, 2013

Supply Relationship of International Power Lithium Battery Separator Manufacturers, 2013

China’s Shipment of Lithium Battery Separator, 2009-2016E

China’s Shipment of Ordinary and High-performance Lithium Battery Separator, 2009-2016E

Proportion of China’s Shipment of High-performance Lithium Battery Separator in Global Total, 2010-2016E

Shipment of China-made Lithium Battery Separator, 2009-2016E

Shipment of China-made Lithium Battery Separator and % in Global Total, 2009-2016E

China-made and Imported Lithium Battery Separator Volume and Import Dependency, 2010-2016E

Import Volume and Value of Polyolefin Lithium Battery Separator in China, 2009-2016E

Import Sources of Polyolefin Lithium Battery Separator in China, 2013

China Lithium Battery Separator Market Size, 2009-2016E

Market Size of Home-made and Imported Lithium Battery Separators in China, 2009-2016E

Average Price of Home-made and Imported Separators in China, 2009-2016E

Market Share of Chinese Lithium Battery Separator Enterprises by Shipment, 2013

Market Share of Chinese Lithium Battery Separator Enterprises by Sales Value, 2013

Techniques and Production Capacities of Chinese Lithium Battery Separator Manufacturers at the End of 2013

Supply Relationship of Chinese Lithium Battery Separator Manufacturers, 2013

Applications of Li-ion Battery

Global Shipment of Notebook PC, Tablet Computer and Mobile Phone, 2012-2016E

Global Shipment of Lithium Battery for Notebook PC, Tablet Computer and Mobile Phone, 2012-2016E

Global Sales Volume of Electric Vehicle, 2008-2016E

Battery Capacity and Cruising Ability of Global Key Electric Vehicles

Single-vehicle Battery Capacity of Global Electric Vehicle, 2008-2016E

Power Battery Demand of Global Electric Vehicle, 2008-2016E

Global Shipment of Lithium Battery, 2008-2016E

Structure (%) of Global Demand for Lithium Battery, 2012-2016E

Global Shipment of Lithium Battery by Demand, 2008-2016E

Global Lithium Battery Industry Scale, 2008-2016E

Electric Vehicle Sales Volume in China, 2008-2016E

Proportion of China’s Sales Volume of Electric Vehicle in Global Total, 2008-2016E

China’s Shipment of Lithium Battery, 2008-2016E

Proportion of China’s Shipment of Lithium Battery in Global Total, 2008-2016E

China Lithium Battery Industry Scale, 2008-2016E

Proportion of China’s Lithium Battery Industry Scale in Global Total, 2008-2016E

China Power Lithium Battery Industry Scale and Its Proportion in the World, 2010-2016E

Proportions of China’s, Japan’s and South Korea’s Shipment of Lithium Battery, 2012-2013

Market Share of World’s Small Lithium Battery Firms, 2013

Market Share of World’s Power Lithium Battery Enterprises, 2013

The Joint-stock Suppliers of Power Lithium Battery in the World

Battery Technologies and Sales Value of Chinese Power Lithium Battery Enterprises, 2013

Operating Revenue Structure of Asahi Kasei, FY2013/14

Battery Separator Micrograph of Asahi Kasei

Lithium Battery Separator (Asia Excluding Japan) Production Bases of Asahi Kasei

Administrative Organization of Asahi Kasei (China)

Lithium Battery Separator (Japan) Production Bases of Asahi Kasei

Lithium Battery Separator Capacity Release of Asahi Kasei, 2004-2013

Contact Means of Battery Separator Marketing Division of Asahi Kasei

Battery Separator Output, Capacity and Capacity Utilization of Asahi Kasei, 2008-2013

Celgard’s Branches Worldwide

Technical Parameters of Celgard’s Battery Separator

Administrative Organization of Celgard (China)

Global Production Bases and Marketing Network of Celgard’s Lithium Battery Separator

Battery Separator Output, Capacity and Capacity Utilization of Celgard, 2008-2013

Battery Separator Investment Plan of Celgard

Equity Structure of Toray Tonen

Battery Separator Output, Capacity and Capacity Utilization of Toray Tonen, 2008-2013

Business Performance of UBE, Sep.2008-FY2013/14

Operating Revenue Structure of UBE, FY2013/14

Contact Means of Battery Separator Business Division of UBE

Battery Separator (Japan) Production Bases of UBE

Battery Separator Output, Capacity and Capacity Utilization of UBE, 2008-2013

Key Subsidiaries under SKI

Battery Separator Output, Capacity and Capacity Utilizaiton of SKI, 2009-2013

Contact Means of Battery Separator Business Division of Entek

Technical Parameters of Entek’s Battery Separator

Operating Revenue Structure of Mitsubishi Chemical, FY2013/14

Global Branches of Mitsubishi Chemical

Lithium Battery Separator Manufacturing Techniques of Mitsubishi Chemical

Operating Revenue Structure of Mitsubishi Chemical, FY2013/14

Technical Performance of Lithium Battery Separator of Mitsubishi Chemical

Global Branches of Mitsubishi Chemical’s Electronic Materials Division

Business Performance of W-Scope, 2010-2014

Battery Separator Marketing Regions of W-Scope, 2013

Gross Margin of W-Scope’s Battery Separator, 2009-2013

Battery Separator Output, Capacity and Capacity Utilization of W-Scope, 2009-2013

Technical Parameters of GRE-P Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Technical Parameters of GRE-T Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Technical Parameters of GRE-H Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Lithium Battery Separator Output, Capacity and Capacity Utilization of Xinxiang Zhongke Science and Technology (GREEN), 2007-2013

Major Customers for Lithium Battery Cell of Shenzhen Senior Technology Material

Global Marketing Network of Shenzhen Senior Technology Material

Wet Process and Dry Process Lithium Battery Separator Micrograph of Shenzhen Senior Technology Material

Special Lithium Battery Separator Micrograph of Shenzhen Senior Technology Material

Lithium Battery Separator Investment and Production Expansion Scheme of Shenzhen Senior Technology Material

Lithium Battery Separator Output, Capacity and Capacity Utilization of Shenzhen Senior Technology Material, 2007-2013

Changes in Equity Structure of Foshan Jinhui Hi-tech Optoelectronic Material

Business Performance of Foshan Jinhui Hi-tech Optoelectronic Material, 2009-2013

Technical Parameters of Ordinary Lithium Battery Separator of Foshan Jinhui Hi-tech Optoelectronic Material

Technical Parameters of Strengthened Lithium Battery Separator of Foshan Jinhui Hi-tech Optoelectronic Material

Lithium Battery Separator Investment and Production Expansion Plan of Foshan Jinhui Hi-tech Optoelectronic Material

Lithium Battery Separator Output, Capacity and Capacity Utilization of Foshan Jinhui Hi-tech Optoelectronic Material, 2008-2013

Business Performance of Cangzhou Mingzhu Plastic, 2009-2014Q1

Operating Revenue Structure of Cangzhou Mingzhu Plastic, 2007-2013

Gross Margin of Main Business of Cangzhou Mingzhu Plastic,2007-2013

Technical Parameters of Lithium Battery Separator of Cangzhou Mingzhu Plastic

Lithium Battery Separator Production & Sales and Revenue of Cangzhou Mingzhu Plastic, 2012-2013

Lithium Battery Separator Investment and Production Expansion Scheme of Cangzhou Mingzhu Plastic

Lithium Battery Separator Output, Capacity and Capacity Utilization of Cangzhou Mingzhu Plastic, 2012-2016

Electric Vehicle Sales Volume of BYD, 2013-Mar.2014

Lithium Battery Capacity and Separator Demand of BYD Electric Vehicle

Power Lithium Battery and Separator Demand of BYD, 2012-2016E

Lithium Battery Separator Revenue and Net Income of Cangzhou Mingzhu Plastic, 2012-2016

Equity Structure of Jiangxi Xian Cai Nanofibers Technology

Operation of Jiangxi Xian Cai Nanofibers Technology, 2012-2013

Technical Parameters of Polyimide (PI) Nano Battery Separator of Jiangxi Xian Cai Nanofibers Technology

Polyimide (PI) Nano Battery Separator Investment Plan of Jiangxi Xian Cai Nanofibers Technology

Lithium Battery Separator Investment Plan of Sinoma Science & Technology

Lithium Battery Separator Investment Plan of Zhejiang Great Southeast

Lithium Battery Separator Investment Plan of Jiangsu Jiujiujiu Technology

Technical Parameters of Lithium Battery Separator Technology of Nantong Tianfeng New Electronic Materials

Development Trend of Li-ion Battery

如果这份报告不能满足您的要求,我们还可以为您定制报告,请 留言说明您的详细需求。

|