|

|

|

报告导航:研究报告—

制造业—汽车

|

|

2016-2020年中国电动汽车驱动电机行业研究报告 |

|

字数:1.9万 |

页数:180 |

图表数:104 |

|

中文电子版:9000元 |

中文纸版:4500元 |

中文(电子+纸)版:9500元 |

|

英文电子版:2550美元 |

英文纸版:2750美元 |

英文(电子+纸)版:2850美元 |

|

编号:LYJ001

|

发布日期:2016-12 |

附件:下载 |

|

|

|

水清木华研究中心《2016-2020年中国电动汽车驱动电机行业研究报告》着重研究了以下内容:

中国新能源汽车驱动电机行业发展状况分析,包括产业链、成本分析、商业模式、竞争格局、主流生产厂商的竞争情况,并对乘用车、商用车驱动电机竞争格局进行了分别阐述;此外,对驱动电机技术现状和发展趋势进行了详尽分析; 中国新能源汽车驱动电机行业发展状况分析,包括产业链、成本分析、商业模式、竞争格局、主流生产厂商的竞争情况,并对乘用车、商用车驱动电机竞争格局进行了分别阐述;此外,对驱动电机技术现状和发展趋势进行了详尽分析;

中国22家企业、全球6家企业分析,包括企业经营状况、发展战略、供应链、新能源汽车驱动电机业务等; 中国22家企业、全球6家企业分析,包括企业经营状况、发展战略、供应链、新能源汽车驱动电机业务等;

新能源汽车驱动电机行业概述,包括汽车驱动电机的定义、分类、上下游产业链分析;中国新能源汽车驱动电机行业运行环境分析,包括政策环境、新能源汽车市场的发展状况及对汽车驱动电机行业的影响; 新能源汽车驱动电机行业概述,包括汽车驱动电机的定义、分类、上下游产业链分析;中国新能源汽车驱动电机行业运行环境分析,包括政策环境、新能源汽车市场的发展状况及对汽车驱动电机行业的影响;

根据中国汽车工业协会的统计,2016年1-6月,我国纯电动汽车产销分别达到13.4万辆和12.6万辆,较上年同期分别增长160.8%和161.6%。由2015年至2016年不同种类的电机在纯电动乘用车领域的市场现状及走势,可得出以下结论:

(1)永磁同步电机是目前电动乘用车的首选电机,并且市场份额在逐步加大;

(2)交流异步电机的市场份额比较稳定,是主流电动乘用车电机之一,其市场份额随着永磁同步电机以及其他类型电机的市场份额增大而逐渐减少。但是接下来较长的一段时期内依然会保持主流地位;

(3)无刷直流电机的市场占有率正急剧下降,2015年上半年为20.3%,当年全年减少至14.8%,至2016年上半年市场占有率不足1%。

(4)混合励磁同步电机越来越受到纯电动乘用车制造商的青睐,市场占有率在逐步提高,由2015年上半年的0.03%,增加到全年的0.1%,再到今年上半年的1.1%。

乘用车多采用永磁同步电机,单套驱动电机系统功率多在30KW-50KW左右,价格多在1-2万元/套,微型电动车由于功率一般在20KW,价格也低至7000元/套,目前乘用车驱动电机系统多采用自产自销(in-house)的配套模式,尤其以比亚迪、众泰、新大洋、上汽、江淮等为代表。而大洋电机(为北汽配套)、上海电驱动(为奇瑞配套)、杭州德沃仕(为众泰配套,被方正电机收购),是为数不多进入主流乘用车厂商供应链的独立电机生产商。

客车驱动电机系统是目前主要的竞争领域,进入厂商众多,2014年市场份额最大的企业是上海电驱动、精进电动和南车时代。100KW的交流异步驱动电机系统单价在10万元/套左右,双电机系统报价则高达30万元/套。

未来5-10年,驱动电机技术将呈现永磁化、集成化、数字化的发展趋势。电机控制及集成技术是企业竞争的焦点,在关键的IGBT芯片封装技术上,以及第三代碳化硅(SiC)IGBT的研发等方面,中国仍有世界先进水平有较大差距,是下一步的研究重点。

就驱动技术来说,目前主要的两种驱动方式为集中驱动和轮毂驱动:

(1)集中电机驱动从传统内燃机车结构改造而来,适合批量生产且较易控制成本,是目前主流电机驱动方式。

(2)“下一代电机及电控系统”很可能是轮毂电机及控制系统。轮毂驱动技术在重量、效率等方面具有一定优势,通用、丰田、奔驰的一些混动车型已经开始应用该种驱动方式,中国也已有自主品牌厂商研发此项技术,目前该技术尚不成熟,也并未大规模应用,但可能是未来电动汽车驱动方式的发展方向。日、美在轮毂电机领域研发超前,行业领导者包括日本富士电机、安川电机,美国Protean Electric等。

China Electric Vehicle Drive Motor Industry Report, 2016-2020 highlights the following:

New energy vehicle drive motor industry in China (industry chain, cost analysis, business model, competitive landscape, competition among major manufacturers, competition pattern of drive motors for passenger car and commercial vehicle; technical status and development trends of drive motor); New energy vehicle drive motor industry in China (industry chain, cost analysis, business model, competitive landscape, competition among major manufacturers, competition pattern of drive motors for passenger car and commercial vehicle; technical status and development trends of drive motor);

22 Chinese and 6 global companies (operation, development strategy, supply chain, new energy vehicle drive motor business, etc.); 22 Chinese and 6 global companies (operation, development strategy, supply chain, new energy vehicle drive motor business, etc.);

New energy vehicle drive motor industry (definition, classification, upstream & downstream industry chain of automotive drive motor); New energy vehicle drive motor industry (definition, classification, upstream & downstream industry chain of automotive drive motor);

Operating environment of new energy vehicle drive motor industry in China (policy, and development of new energy vehicle market and its impact on automotive drive motor industry). Operating environment of new energy vehicle drive motor industry in China (policy, and development of new energy vehicle market and its impact on automotive drive motor industry).

China produced 134,000 units and sold 126,000 units of battery electric vehicles in the first six months of 2016, a surge of 160.8% and 161.6% over the same period of last year, according to the China Association of Automotive Manufacturers (CAAM). Adoption of motors in battery electric passenger car may lead to the following conclusions:

(1) Permanent magnet synchronous motor (PMSM) is the first choice for electric passenger car and finds increasing market share;

(2) With stable market share, AC asynchronous motor is one of mainstream motors for electric passenger car and will suffer a gradual decline in market share along with expansion of PMSM and other types of motors but still remain dominant for a longer period of time to come;

(3) Brushless DC motor experiences a collapse in market share, standing at 20.3% in the first half of 2015 and 14.8% at the end of the year, and less than 1% in the first six months of 2016;

(4) Hybrid excitation synchronous machine (HESM) is increasingly favored by battery electric car manufacturers with a higher market share from 0.03% in 2015H1 to 0.1% throughout the year and 1.1% in 2016H1.

Passenger cars mostly adopt PMSM; a single unit of drive motor system often has a power of 30KW-50KW and is priced at RMB10,000-20,000. As the power of drive motor for mini electric vehicle is generally 20KW, the price falls to RMB7,000/unit accordingly. Passenger car drive motor system now usually adopts the model of in-house, which prevails in companies like BYD, ZOTYE, Xin Dayang, SAIC Motor, and JAC Motors. And Zhongshan Broad-ocean Motor (serving BAIC Motor), Shanghai Edrive (serving Chery), Hangzhou Dewos Electric Technology (serving ZOTYE and acquired by Zhejiang Founder Motor) are a few independent motor manufacturers that have entered the supply chain of mainstream passenger car makers.

Bus drive motor system is the field that is highly competitive with a large number of manufacturers. The companies with the biggest market shares were Shanghai Edrive, Jing-Jin Electric and Hunan CRRC Times Electric Vehicle in 2014. 100KW AC asynchronous drive motor is priced at around RMB10,000/unit, and dual-motor system is quoted at RMB300,000/unit.

Over the next five to ten years, drive motor technology will develop towards permanent magnetization, integration, and digitalization. Motor control and integration technology will be the focus of competition among enterprises. China lags far behind the advanced world levels in the aspects of key IGBT chip packaging technology and 3rd-generation SiC IGBT research and development, which will be prioritized in the future.

With regard to drive technology, there are two main modes: centralized drive and hub drive.

(1) Centralized motor drive is transformed from structure of traditional diesel locomotive, is suitable for mass production, and has easily controllable cost, enabling it the mainstream motor drive mode.

(2) “Next-generation motor and electric control system” is likely to be hub motor and control system. Enjoying certain advantages in weight and efficiency, hub drive technology has started to be adopted in some hybrids by GM, Toyota and Benz and to be developed by some domestic makers with own brands. The technology now is still immature and has not been applied massively, but it may be the development direction of EV drive mode in the future. Japan and U.S. are way ahead in hub motor development, with industry leaders including Japanese Fuji Electric and Yasukawa Electric, and American Protean Electric.

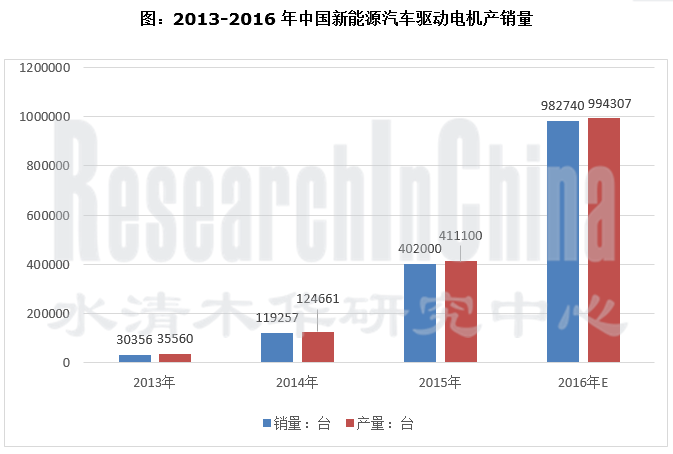

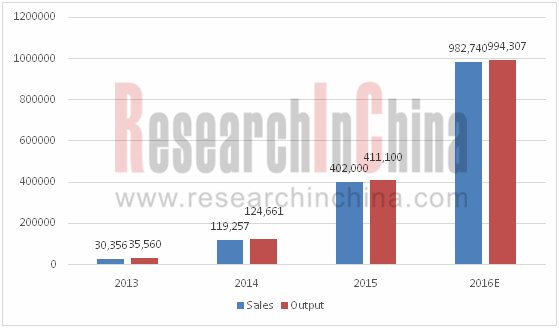

New Energy Vehicle Drive Motor Output and Sales in China, 2013-2016

第一章 电动汽车驱动电机行业概述

1.1 驱动电机介绍

1.2 驱动电机控制器介绍

1.3驱动电机应用领域

1.3.1 纯电动汽车

1.3.2混合动力汽车

第二章 中国电动汽车行业分析

2.1行业政策

2.1.1 财政补贴政策

2.1.2 示范推广政策

2.1.3 蓄电池回收利用政策

2.1.4 税收优惠政策

2.1.5 生产许可政策

2.2 电动汽车市场

2.2.1 整体市场

2.2.2 电动乘用车市场

2.2.3 电动商用车市场

第三章 中国电动汽车驱动电机行业分析

3.1 产业链

3.2 市场规模

3.3 主要厂商及竞争格局

3.3.1 整体竞争格局

3.3.2 乘用车驱动电机竞争格局

3.3.3 客车驱动电机竞争格局

3.4 技术发展趋势

3.4.1 技术现状

3.4.2 技术趋势—永磁化

3.4.3 技术趋势—集成化

3.4.4 技术趋势—数字化

3.4.5 技术趋势—轮毂电机

3.4.6 电动汽车混合驱动与混合制动系统现状及展望

第四章 中国驱动电机行业主要企业

4.1 大洋电机

4.1.1 企业简介

4.1.2 经营情况

4.1.3 发展战略

4.1.4 电动汽车电机业务

4.1.5 驱动电机投资与产能

4.2 上海电驱动

4.2.1 公司简介

4.2.2 经营情况

4.2.3 供应链分析

4.2.4 驱动电机产品及技术

4.2.5 驱动电机投资与产能

4.3 中车时代电动

4.3.1 企业简介

4.3.2 经营情况

4.3.3 驱动电机产品

4.3.4 研发

4.3.5 驱动电机投资与产能

4.4 万向钱潮

4.4.1 企业简介

4.4.2 经营情况

4.4.3 电动汽车电机业务

4.5 上海大郡

4.5.1 企业简介

4.5.2 经营情况

4.5.3 供应链分析

4.5.4 驱动电机产品

4.6 精进电动

4.6.1 企业简介

4.6.2 经营情况

4.6.3 电动汽车电机业务

4.7 方正电机

4.7.1 企业简介

4.7.2 经营情况

4.7.3 供应链

4.7.4 驱动电机产品

4.7.5 驱动电机投资

4.7.6 驱动电机产能

4.8 卧龙电气

4.8.1 企业简介

4.8.2 经营情况

4.8.3 电动汽车电机业务

4.9 信质电机

4.9.1 企业简介

4.9.2 经营情况

4.9.3 电动汽车电机业务

4.10 江特电机

4.10.1 企业简介

4.10.2 经营情况

4.10.3 电动汽车电机业务

4.11 北京中纺锐力机电

4.11.1 企业简介

4.11.2 经营情况

4.11.3 电动汽车电机业务

4.12 尤奈特电机

4.12.1 企业简介

4.12.2 经营情况

4.12.3 电动汽车电机业务

4.13 其他厂商

4.13.1 大连电机

4.13.2 深圳大地和

4.13.3 联合汽车电子

4.13.4 兰基电动汽车

4.13.5 华域汽车电动系统

4.13.6 江苏微特利电机制造

4.13.7 无锡迈为电子技术

4.13.8 上海赢双电机

4.13.9锦 州汉拿电机

第五章 全球驱动电机行业主要企业

5.1 罗伯特博世(Robert Bosch)

5.1.1 企业简介

5.1.2 经营情况

5.1.3 电动汽车电机业务

5.2 采埃孚(ZF Friedrichshafen AG)

5.2.1 企业简介

5.2.2 经营情况

5.2.3 电动汽车电机业务

5.3 大陆集团(Continental AG)

5.3.1 企业简介

5.3.2 经营情况

5.3.3 电动汽车电机业务

5.4 爱信精机(Aisin AW)

5.4.1 企业简介

5.4.2 经营情况

5.4.3 电动汽车电机业务

5.5 现代摩比斯(MOBIS)

5.5.1 企业简介

5.5.2 经营情况

5.5.3 电动汽车电机业务

5.6 AC Propulsion(ACP)

5.6.1 企业简介

5.6.2 电动汽车电机业务

5.7 西门子(SIEMENS)

5.7.1 企业简介

5.7.2 经营情况

5.7.3 电动汽车电机业务

1 Overview of EV Drive Motor Industry

1.1 Introduction to Drive Motor

1.2 Introduction to Drive Motor Controller

1.3 Applications of Drive Motor

1.3.1 Battery Electric Vehicle (BEV)

1.3.2 Hybrid Vehicle

2 China Electric Vehicle Industry

2.1 Policies

2.1.1 Fiscal Subsidy Policy

2.1.2 Demonstration& Promotion Policy

2.1.3 Storage Battery Recycling Policy

2.1.4 Tax Preference Policy

2.1.5 Production Permit Policy

2.2 Electric Vehicle Market

2.2.1 Overall Market

2.2.2 Electric Passenger Car Market

2.2.3 Electric Commercial Vehicle Market

3 China EV Drive Motor Industry

3.1 Industrial Chain

3.2 Market Size

3.3 Major Players and Competitive Landscape

3.3.1 Overall Competition Pattern

3.3.2 Competition Pattern of Passenger Car Drive Motors

3.3.3 Competition Pattern of Bus Drive Motors

3.4 Trends of Technological Advancement

3.4.1 Status Quo of Technologies

3.4.2 Trend -Permanent Magnetization

3.4.3 Trend - Integration

3.4.4 Trend - Digitalization

3.4.5 Trend - Hub Motor

3.4.6 Status Quo and Prospects of EV Hybrid Drive and Hybrid Brake System

4 Major Chinese Drive Motor Companies

4.1 Zhongshan Broad-Ocean Motor Co., Ltd.

4.1.1 Profile

4.1.2 Operation

4.1.3 Development Strategy

4.1.4 EV Motor Business

4.1.5 Drive Motor Investment and Capacity

4.2 Shanghai Edrive Co., Ltd.

4.2.1 Profile

4.2.2 Operation

4.2.3 Supply Chain

4.2.4 Drive Motors & Technologies

4.2.5 Drive Motor Investment and Capacity

4.3 Hunan CRRC Times Electric Vehicle Co., Ltd.

4.3.1 Profile

4.3.2 Operation

4.3.3 Drive Motors

4.3.4 R&D

4.3.5 Drive Motor Investment and Capacity

4.4 WanxiangQianchao Co., Ltd.

4.4.1 Profile

4.4.2 Operation

4.4.3 EV Motor Business

4.5 Shanghai DAJUN Technologies, Inc.

4.5.1 Profile

4.5.2 Operation

4.5.3 Supply Chain

4.5.4 Drive Motors

4.6 Jing-Jin Electric (JJE)

4.6.1 Profile

4.6.2 Operation

4.6.3 EV Motor Business

4.7 Zhejiang Founder Motor Co., Ltd.

4.7.1 Profile

4.7.2 Operation

4.7.3 Supply Chain

4.7.4 Drive Motors

4.7.5 Drive Motor Investment

4.7.6 Drive Motor Capacity

4.8 Wolong Electric Group Co., Ltd.

4.8.1 Profile

4.8.2 Operation

4.8.3 EV Motor Business

4.9 Xinzhi Motor Co., Ltd.

4.9.1 Profile

4.9.2 Operation

4.9.3 EV Motor Business

4.10 Jiangxi Special Electric Motor Co., Ltd.

4.10.1 Profile

4.10.2 Operation

4.10.3 EV Motor Business

4.11 ChinaTexMechanical&ElectricalEngineeringLtd. (China Tex MEE)

4.11.1 Profile

4.11.2 Operation

4.11.3 EV Motor Business

4.12 Unite Motor Co., Ltd.

4.12.1 Profile

4.12.2 Operation

4.12.3 EV Motor Business

4.13 Others

4.13.1 Dalian Motor Group Co., Ltd.

4.13.2 Shenzhen Greatland Electrics Inc.

4.13.3 United Automotive Electronic Systems Co., Ltd. (UAES)

4.13.4 JinanLanji New Energy Vehicle Co., Ltd.

4.13.5 Huayu Automotive Electric System Co., Ltd.

4.13.6 Jiangsu Weiteli Motor Limited By Share Ltd.

4.13.7 Wuxi MyWay Electronic Technology Co., Ltd.

4.13.8 Shanghai Win Double Electric Co., Ltd.

4.13.9 Jinzhou Halla Electrical Equipment Co., Ltd.

5 Major Global Drive Motor Companies

5.1 Robert Bosch

5.1.1 Profile

5.1.2 Operation

5.1.3 EV Motor Business

5.2 ZF Friedrichshafen AG

5.2.1 Profile

5.2.2 Operation

5.2.3 EV Motor Business

5.3 Continental AG

5.3.1 Profile

5.3.2 Operation

5.3.3 EV Motor Business

5.4 Aisin AW

5.4.1 Profile

5.4.2 Operation

5.4.3 EV Motor Business

5.5 Hyundai Mobis

5.5.1 Profile

5.5.2 Operation

5.5.3 EV Motor Business

5.6 AC Propulsion (ACP)

5.6.1 Profile

5.6.2 EV Motor Business

5.7 Siemens

5.7.1 Profile

5.7.2 Operation

5.7.3 EV Motor Business

图:驱动电机驱动系统的基本构成

表:电动汽车驱动电机和传统电机的主要参数对比

表:电动汽车驱动电机分类

表:不同类别电动汽车驱动电机技术特点

表:不同类别电动汽车驱动电机性能参数

图:驱动电机控制器结构图

图:不同类型驱动电机的控制策略及应用现状

图:纯电动汽车驱动电机系统结构

图:混合动力汽车驱动电机系统工作原理及应用

图:轻度混合动力汽车驱动电机系统结构

图:增程式动力系统结构

图:比亚迪插电式混合动力汽车“唐”驱动电机系统

图:丰田普锐斯双电机混合动力发动机

图:2015年1月-2016年10月中国节能与新能源(EV、PHEV)乘用车销量

图:2014年-2016年9月全球新能源车(EV&PHEV)销量

表:2016年1-10月中国电动乘用车(EV、PHEV)(分车型)销量

表:2016年1- 10月中国节能与新能源乘用车(EV、PHEV、HEV)进口量

图:2015年1月 - 2016年10月中国节能与新能源(EV、PHEV)乘用车销量

表:2016年1-10月中国节能与新能源(EV、PHEV、HEV)乘用车销量(附表)

图:永磁同步驱动电机的价格构成

图:电机控制器成本占比

图:2012-2020年中国电动汽车驱动电机系统市场规模

表:驱动电机及系统企业主要类型

表:2016年1-7月驱动电机生产企业电机及控制器装机量

表:国内主要驱动电机及控制器厂商

图:国内电机及控制器厂商的7种供应模式

表:全球电机控制器IBGT生产商

表:第288批新车公示中新能源乘用车配套的电机企业

表:电机产业分布及配套关系

图:2013-2016年中国新能源汽车驱动电机产销量

图:2016年1-6月我国生产的纯电动乘用车采用的电机类型

图:2015年1-12月我国生产的纯电动乘用车采用的电机类型

图:中国主要电动客车驱动电机及控制器配套关系

表:集中式和轮毂电机驱动对比

表:2016年上半年全球销量前十的电动汽车电驱动系统构型

表:中国电动汽车“十二五” (2011-2015年)专项规划

表:电机及控制器集成化方法及效果

图:博格华纳(左)与采埃孚(右)的驱动电机与单级减速器集成

图:电机控制系统数字化

图:IGBT技术发展路径

图:内转子结构的轮毂电机驱动系统结构图

图:轮毂电机可匹配各种新能源车型

图:2011-2016第三季度大洋电机经营情况

表:2016年上半年大洋电机(分行业)营收构成

图:2011-2016上半年大洋电机(分地区)营收占比

图:2009-2016上半年大洋电机毛利率

图:2015-2016上半年大洋电机(分产品)毛利率

图:大洋电机十年发展战略

表:大洋电机十年发展战略及实施主体

表:大洋电机主要子公司

图:大洋电机在建电动汽车电驱动系统项目情况

图:上海电驱动股权结构图(收购前)

表:2015-2022年驱动电机系统销量

图:2009-2016上半年上海电驱动经营业绩

表:上海电驱动已生产的驱动电机系统类型及参数

表:上海电驱动驱动电机系统尺寸及外观

表:2016年公交客车月度销量排名

表:中车时代电动已生产的驱动电机类型及参数

图:2011-2016上半万向钱潮营业收入及净利润

图:2011-2016上半年万向钱潮(分产品)营收占比

表:2011-2016上半年万向钱潮(分产品)营收情况

图:2011-2016上半年万向钱潮(分地区)营收占比

表:2015年万向钱潮来自前五名客户的营业收入情况

图:2012-2016上半万向钱潮毛利率

图:2011-2016上半年万向钱潮(分产品)毛利率

图:2012-2016上半年上海大郡经营业绩

表:大郡产品主要客户

图:上海大郡驱动电动产品体系

图:上海大郡驱动电动产品性能参数及应用

表:精进电动已生产的驱动电机主要规格

图:2011-2016年前三季度方正电机营业收入及净利润

图:2011-2016上半年方正电机(分产品)营收占比

表:2011-2016上半年方正电机(分产品)营收情况(百万元,CNY)

图:2011-2016上半年方正电机(分地区)营收占比

图:2011-2016H1方正电机毛利率

表:方正机电电动物流车动力总成系统2016年订单预计

表:方正机电乘用车动力总成系统2016年订单预计

图 :电动汽车驱动控制领域架构及布局

图:2011-2016前三季度卧龙电气营业收入及净利润

图:2011-2016上半年卧龙电气(分产品)营收占比

表:卧龙电气(分产品)营业收入(百万元,CNY)

图:2011-2016上半年卧龙电气(分地区)营收占比

图:2011-2016上半年卧龙电气毛利率

图:2011-2016上半年卧龙电气(分产品)毛利率

图:2010-2016年前三季度年信质电机营业收入及净利润

图:2015-2016上半年信质电机(分产品)营收占比

图:2011-2016上半年信质电机(分地区)营收占比

表:2015年信质电机来自前五名客户的营业收入情况

图:2011-2016上半年信质电机毛利率

表:2015-2016上半年信质电机(分产品)毛利率

图:2011-2016年前三季度江特电机营业收入及净利润

图:2016上半年江特电机(分产品)营收占比

图:2011-2016上半年江特电机(分地区)营收占比

图:2012-2016上半年江特电机毛利率

表:2015-2016上半年江特电机(分产品)毛利率

表:江特电机主营电动汽车业务的子公司

表:江特电机2014年驱动电机研发情况

表:北京中纺锐力机电已生产的电动汽车SRD电机主要规格

图:2010-2015博世营业收入及净利润

表:2015年博世(分部门)营收构成

图:2010-2015年博世(分地区)营收占比

图:2010-2015年博世毛利率

图:2011-2016上半年采埃孚营业收入及净利润

表:2015年采埃孚(分部门)营收构成

图:2014-2015年采埃孚(分地区)营收占比

图:2010-2015年采埃孚毛利率

图:2011-2016上半年大陆集团营业收入及净利润

表:2011-2016上半年大陆集团(分部门)营收构成

图:2010-2015年大陆集团(分地区)营收占比

图:2010-2016H1大陆集团毛利率

图:FY2011-FY2015爱信精机营业收入及净利润

表:FY2011-FY2015爱信精机(分部门)营收构成

图:FY2011-FY2015爱信精机(分地区)营收占比

表:2015财年爱信精机来自前五名客户的营业收入情况

图:FY2011-FY2015爱信精机毛利率

图:2010-2016年9月现代摩比斯营业收入及净利润

图:现代摩比斯分地区收入构成

图:FY2010-FY2016西门子营业收入及净收益

表:西门子乘用车驱动电机规格和外观

表:西门子商用车ELFA驱动系统的构成

Composition of Drive Motor’s Driving System

Comparison of Parameters between EV Drive Motor and Traditional Motor

Classification of EV Drive Motor

Technical Features of Various EV Drive Motors

Parameters of Various EV Drive Motors

Block Diagram of Drive Motor Controller

Control Strategies and Current Application of Various Drive Motors

Structure of BEV Drive Motor System

Operating Principle and Application of Hybrid Vehicle Drive Motor System

Structure of Mild Hybrid Vehicle Drive Motor System

Structure of Range-extended Power System

Drive Motor System of BYD’s PHEV “Tang”

Dual-motor Hybrid Engine of Toyota Prius

Sales Volume of Energy-efficient and New Energy (EV & PHEV) Passenger Cars in China, Jan.2015-Oct.2016

Sales Volume of New Energy Vehicle (EV & PHEV) Worldwide, 2014-Sept.2016

Sales Volume of Electric Passenger Cars (EV & PHEV) (by Model) in China, Jan-Oct 2016

Import Volume of Energy-efficient and New Energy Passenger Vehicle (EV, PHEV, HEV) in China, Jan-Oct 2016

Sales Volume of Energy-efficient and New Energy (EV & PHEV) Passenger Cars in China, Jan 2015-Oct 2016

Sales Volume of Energy-efficient and New Energy (EV, PHEV, HEV) Passenger Cars in China, Jan-Oct 2016 (Attached Table)

Price Structure of Permanent Magnet Synchronous Drive Motor

Cost Percentage of Motor Controller

Chinese Market Size of EV Drive Motor System, 2012-2020E

Main Types of Drive Motor and System Enterprises

Motor and Controller Installations of Drive Motor Manufacturers, Jan-Jul 2016

Major Drive Motor and Controller Manufacturers in China

Seven Supply Modes of Chinese Motor and Controller Manufacturers

Motor Controller IGBT Manufacturers Worldwide

Motor Enterprises Supporting New Energy Passenger Cars in the 288th Batch New Vehicle Publicity

Motor Industry Distribution and Supporting Relationship

Production and Sales Volume of New Energy Vehicle Drive Motors in China, 2013-2016

Types of Motors Adopted by Pure Electric Passenger Cars Made in China, Jan-Jun 2016

Types of Motors Adopted by Pure Electric Passenger Cars Made in China, Jan-Dec 2015

Supply Relation between Major Electric Bus Drive Motors and Controllers in China

Drive Comparison between Centralized and Hub Motors

Structure of Electric Drive Systems of Top 10 Best-selling EVs Worldwide, 2016H1

Special Planning for China Electric Vehicle Industry during 2011-2015

Motor and Controller IntegrationMethods and Effect

BorgWarner (Left) and ZF (Right)’s Drive Motor and Single-stage Decelerator Integration

Digitalization of Motor Control System

Development Roadmap of IGBT Technology

Block Diagram for Driving System of Hub Motor with Inner Rotor Structure

Hub Motor Suited for All Kinds of New Energy Vehicle Models

Operation of Zhongshan Broad-Ocean Motor, 2011-2016Q3

Revenue Structure of Zhongshan Broad-Ocean Motor (by Sector), 2016H1

Revenue Structure of Zhongshan Broad-Ocean Motor (by Region), 2011-2016H1

Gross Margin of Zhongshan Broad-Ocean Motor, 2009-2016H1

Gross Margin of Zhongshan Broad-Ocean Motor (by Product), 2015-2016H1

Ten-year Development Strategy of Zhongshan Broad-Ocean Motor

Ten-year Development Strategy and Executors of Zhongshan Broad-Ocean Motor

Major Subsidiaries of Zhongshan Broad-Ocean Motor

EV Electric Drive System Projects under Way of Zhongshan Broad-Ocean Motor

Equity Structure of Shanghai Edrive (before Acquisition)

Drive Motor System Sales Volume of Shanghai Edrive, 2015-2022E

Operating Performance of Shanghai Edrive, 2009-2016H1

Types and Parameters of Drive Motor Systems Made by Shanghai Edrive

Dimensions and Appearance of Drive Motor System of Shanghai Edrive

Ranking by Monthly Sales Volume of Public Transportation Buses, 2016

Types and Parameters of Drive Motors Made by Hunan CRRC Times Electric Vehicle

Revenue and Net Income of WanxiangQianchao, 2011-2016H1

Revenue Structure of WanxiangQianchao (by Product), 2011-2016H1

Revenue Breakdown of WanxiangQianchao (by Product), 2011-2016H1

Revenue Structure of WanxiangQianchao (by Region), 2011-2016H1

WanxiangQianchao’s Revenue from Top 5 Customers, 2015

Gross Margin of WanxiangQianchao, 2012-2016H1

Gross Margin of WanxiangQianchao (by Product), 2011-2016H1

Operating Performance of Shanghai DAJUN Technologies, 2012-2016H1

Major Customers of Shanghai DAJUN Technologies

Drive Motor Product System of Shanghai DAJUN Technologies

Parameters and Application of Drive Motor Products of Shanghai DAJUN Technologies

Specifications of Drive Motors Made by JJE

Revenue and Net Income of Zhejiang Founder Motor, 2011-2016Q1-Q3

Revenue Structure of Zhejiang Founder Motor (by Product), 2011-2016H1

Revenue Breakdown of Zhejiang Founder Motor (by Product), 2011-2016H1

Revenue Structure of Zhejiang Founder Motor (by Region), 2011-2016H1

Gross Margin of Zhejiang Founder Motor, 2011-2016H1

Electric Logistics Vehicle Powertrain System Orders (Estimated) of Zhejiang Founder Motor, 2016

Passenger Car Powertrain SystemOrders (Estimated) of Zhejiang Founder Motor, 2016

Framework and Layout in EV Drive Control Field

Revenue and Net Income of Wolong Electric Group, 2011-2016Q1-Q3

Revenue Structure of Wolong Electric Group (by Product), 2011-2016H1

Revenue Breakdown of Wolong Electric Group (by Product), 2011-2016H1

Revenue Structure of Wolong Electric Group (by Region), 2011-2016H1

Gross Margin of Wolong Electric Group, 2011-2016H1

Gross Margin of Wolong Electric Group, (by Product), 2011-2016H1

Revenue and Net Income of Xinzhi Motor, 2010-2016Q1-Q3

Revenue Structure of Xinzhi Motor (by Product), 2015-2016H1

Revenue Structure of Xinzhi Motor (by Region), 2011-2016H1

Xinzhi Motor’s Revenue from Top 5 Customers, 2015

Gross Margin of Xinzhi Motor, 2011-2016H1

Gross Margin of Xinzhi Motor (by Product), 2015-2016H1

Revenue and Net Income of Jiangxi Special Electric Motor, 2011-2016Q1-Q3

Revenue Structure of Jiangxi Special Electric Motor (by Product), 2016H1

Revenue Structure of Jiangxi Special Electric Motor (by Region), 2011-2016H1

Gross Margin of Jiangxi Special Electric Motor, 2012-2016H1

Gross Margin of Jiangxi Special Electric Motor (by Product), 2015-2016H1

Jiangxi Special Electric Motor’s Subsidiaries Involved in EV Business

Drive Motor R&D of Jiangxi Special Electric Motor, 2014

Specifications of EV SRD Motor Made by China Tex MEE

Revenue and Net Income of Bosch, 2010-2015

Revenue Structure of Bosch (by Division), 2015

Revenue Structure of Bosch (by Region), 2010-2015

Gross Margin of Bosch, 2010-2015

Revenue and Net Income of ZF Friedrichshafen AG, 2011-2016H1

Revenue Structure of ZF Friedrichshafen AG (by Division), 2015

Revenue Structure of ZF Friedrichshafen AG (by Region), 2014-2015

Gross Margin of ZF Friedrichshafen AG, 2010-2015

Revenue and Net Income of Continental AG, 2011-2016H1

Revenue Structure of Continental AG (by Division), 2011-2016H1

Revenue Structure of Continental AG (by Region), 2010-2015

Gross Margin of Continental AG, 2010-2016H1

Revenue and Net Income of Aisin AW, FY2011-FY2015

Revenue Structure of Aisin AW (by Division), FY2011-FY2015

Revenue Structure of Aisin AW (by Region), FY2011-FY2015

Aisin AW’s Revenue from Top 5 Customers, FY2015

Gross Margin of Aisin AW, FY2011-FY2015

Revenue and Net Income of Hyundai Mobis, 2010-Sept.2016

Revenue Structure of Hyundai Mobis (by Region),2016H1

Revenue and Net Income of Siemens, FY2010-FY2016

Specifications and Appearance of Passenger Car Drive Motor of Siemens

Composition of Commercial Vehicle ELFA Drive System of Siemens

如果这份报告不能满足您的要求,我们还可以为您定制报告,请 留言说明您的详细需求。

|