|

|

|

报告导航:研究报告—

制造业—汽车

|

|

2017-2020年全球及中国动力电池管理系统(BMS)行业研究报告 |

|

字数:2.3万 |

页数:155 |

图表数:151 |

|

中文电子版:13000元 |

中文纸版:6500元 |

中文(电子+纸)版:13500元 |

|

英文电子版:2600美元 |

英文纸版:2800美元 |

英文(电子+纸)版:2900美元 |

|

编号:JAF005

|

发布日期:2017-09 |

附件:下载 |

|

|

|

电池管理系统(BMS)是纯电动和混合动力汽车的一个关键组成部分,主要由电池电子部件(Battery electronics)和电池控制单元(Battery control unit)组成,BE负责采集电池的电流、电压、温度等相关数据并传输给BCU进行控制,BCU还负责与其他控制单元进行信息交互。

BMS最核心的三大功能为电芯监控、荷电状态(SOC)估算以及单体电池均衡。BMS监测到单体锂电池芯的工作温度和电量,并自动采取措施均衡单体锂电池芯的充放电电流和防止过温现象发生。能使电动汽车动力电池在各种工作条件下获得最佳的性能、最长的使用寿命,是发展电动汽车的关键技术之一。

2016年全球电动乘用车销量达74.8万辆,同比2015年增长36.1%,主要的增长点来自于中国和欧洲。国外动力电池BMS普遍采用主动均衡技术,单车成本较高,2016年全球BMS市场规模达到41.7亿美元,预计2025年将达到111.7亿美元,2017-2022年间复合增长率11.6%。

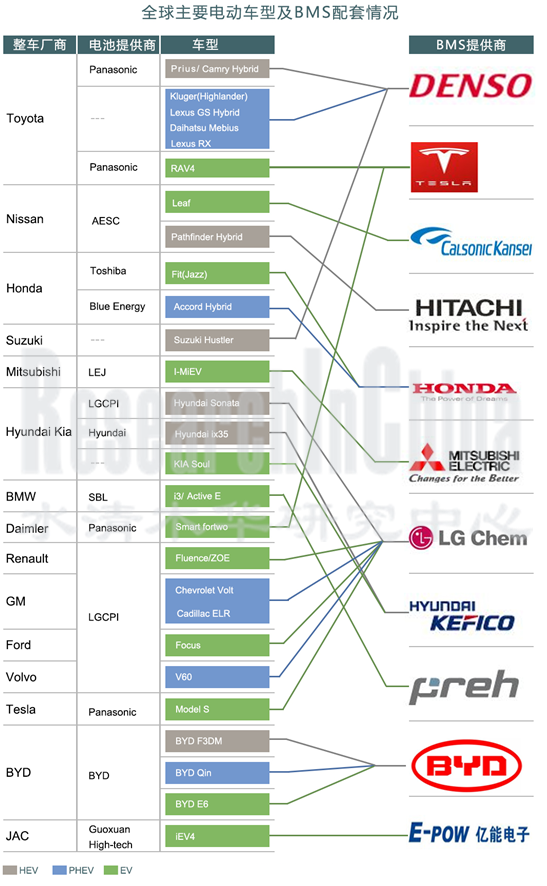

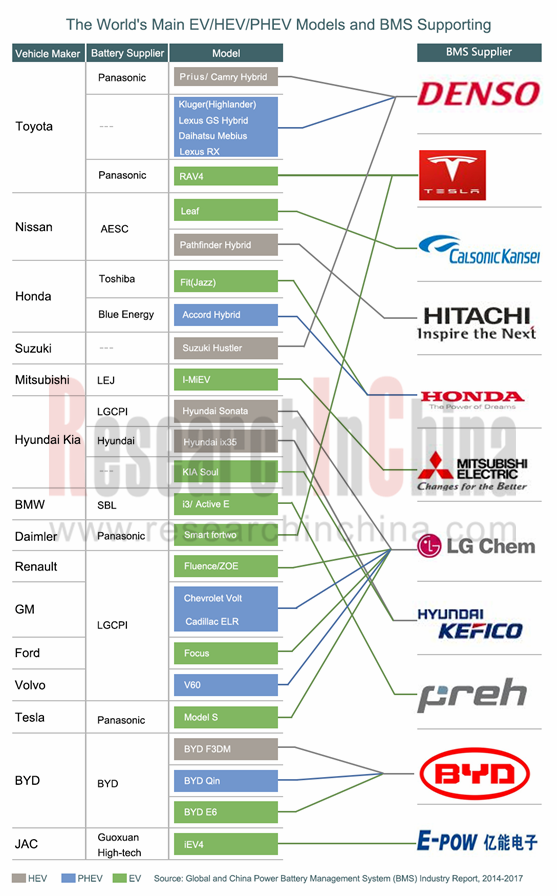

以Denso、Preh为代表的传统汽车零部件厂商凭借在整车厂供应链中的重要地位,已经抢占了先机。前者作为丰田汽车最重要的零部件供应商,先后为Prius、Camry Hybrid等车型提供电池管理模块;后者除了为宝马i系列纯电动车配套之外,还借助母公司均胜电子的资源开拓中国市场。

电芯厂如LGC在于原有客户保持合作的基础上,试图通过逐渐收缩BMS的功能范围,使其简单和通用化,并将软件及数据服务单独剥离出来单独提供给整车厂。整车企业中,特斯拉的BMS成熟且复杂,其下一代技术将转为适用于更大的单体电芯。

2016年中国电动汽车生产51.7万辆,销售50.7万辆,同比分别增长51.7%和53%。带动2016 年中国动力电池 BMS 市场规模暴增至约 50 亿,预计2020 年销售规模将进一步增长至140-150亿;

未来5年,中国动力电池BMS市场面临以下发展趋势:

(1)政策层面,出于对新能源汽车安全性的要求,中汽研旗下全国汽车标准化委员会正在制定中国电池管理系统(BMS)国标,BMS技术标准将日趋严格;

(2)随着三元锂电池渗透率提升,对于电池安全性管理要求更高;

(3)BMS 核心在主动式电池均衡和 SOC 估算算法设计,轻资产硬件设计公司将有较高盈利能力;

(4)整车厂和电芯厂都有向 BMS 产业链延伸规划,技术壁垒和研发投入制约,上下游企业延伸难度高, BMS 整体解决外包是一种合理市场行为。

竞争格局方面,中国BMS市场主要进入三类企业:

(1)第三方BMS厂商,如亿能电子、科列技术、华霆动力、金杯新能源等。其中亿能电子进入较早,其BMS产品配套了长安、东风、北汽、福田、江淮、众泰等多款型号的电动汽车;这类厂商规模占整体市场的42%;

(2)电池模组以及PACK封装企业,如国轩高科、CATL、沃特玛、欣旺达等通过自主研发或者合作进入市场;这类厂商规模占整体市场的37%;

(3)整车厂商,比亚迪和北汽新能源布局较完善,比亚迪集电池、BMS、电动汽车研发于一身,在成本和效率方面拥有优势,而北汽新能源收购Atieva后拥有了BMS研发能力,不再需要第三方BMS厂商为其供应;这类厂商规模占整体市场的21%;

水清木华研究中心《2017-2020年全球及中国动力电池管理系统(BMS)行业研究报告》主要内容包括:

全球及中国电动汽车市场发展概况(包括概况、市场规模、整车产量、销量等) 全球及中国电动汽车市场发展概况(包括概况、市场规模、整车产量、销量等)

全球BMS行业发展概况(包括发展现状及预测、市场规模、技术趋势等) 全球BMS行业发展概况(包括发展现状及预测、市场规模、技术趋势等)

中国BMS行业发展概况(包括发展现状及预测、价格成本、市场规模、竞争格局、供应配套、技术趋势等) 中国BMS行业发展概况(包括发展现状及预测、价格成本、市场规模、竞争格局、供应配套、技术趋势等)

全球BMS行业主要生产企业(包括公司及子公司营业收入、营收构成、净利润、研发情况、产品概况、整车厂配套、最新动态、在华业务等) 全球BMS行业主要生产企业(包括公司及子公司营业收入、营收构成、净利润、研发情况、产品概况、整车厂配套、最新动态、在华业务等)

中国BMS行业主要生产企业,分独立第三方、电芯厂商、OEM整车厂商等三类(包括公司及子公司营业收入、营收构成、净利润、研发情况、产品概况、整车厂配套、最新项目等) 中国BMS行业主要生产企业,分独立第三方、电芯厂商、OEM整车厂商等三类(包括公司及子公司营业收入、营收构成、净利润、研发情况、产品概况、整车厂配套、最新项目等)

BMS芯片行业主要生产企业(包括公司营业收入、营收构成、净利润、BMS芯片解决方案等) BMS芯片行业主要生产企业(包括公司营业收入、营收构成、净利润、BMS芯片解决方案等)

BMS (Battery Management System), as a key integral of battery electric vehicle and hybrid vehicle, is primarily composed of battery electronics (BE) and battery control unit (BCU), with the former responsible for collecting such data about battery as current, voltage and temperature and transmitting them to BCU, and the latter BCU accountable for information exchanges with other control units.

BMS has three core functions consisting of cell monitoring, SOC (State of Charge) estimation, and single battery equalization. BMS monitors the working temperature and quantity of electricity of a single lithium battery cell and automatically adopts measures to equalize the charging and discharging current and prevent the overheating temperature, enabling EV power battery to gain best performance and the longest life cycle under any circumstances, and being a kind of crucial technology to develop electric vehicle.

In 2016, a total of 748,000 electric passenger cars were sold worldwide, surging by 36.1% from a year earlier, with increments mainly from China and Europe. Foreign power battery BMS generally renders the active equalization technology and single car has higher costs. The global BMS market size reported USD4.17 billion in 2016, and is expected to reach USD11.17 billion in 2025, presenting a CAGR of 11.6% during 2017-2025.

The traditional auto parts vendors represented by Denso and Preh have seize the initiative by dint of their key roles in vehicle supply chain. Denso as the most important supplier of parts for Toyota has provided BMS modules to vehicle models like Prius and Camry Hybrid successively, while Preh not only supplies products to BMW I series BEVs but vigorously explore Chinese market by resorting to the resources of its parent company Joyson Electronics.

Cell vendors like LGC attempts to constricts the functional range of BMS and make it simple and universal, and to spin off software and data services as a separate supply to automakers. Among carmakers, Tesla BMS is mature and sophisticated and its next-generation technology will be applicable to bigger single cell.

In 2016, China produced 517,000 electric vehicles and sold 507,000 ones, a respective upsurge of 51.7% and 53% year on year, helping Chinese market size of power battery BMS grow explosively to about RMB5 billion in 2016 and as expected to RMB14 billion to RMB15 billion in 2020.

In the upcoming five years, Chinese power battery BMS market will show the trends as follows:

1) As concerns policy, National Technical Committee of Auto Standardization is drafting national BMS standards out of consideration for requirements on NEV (New Energy Vehicle) safety. BMS technical norms become ever stringent;

2) As the penetration rate of ternary lithium battery rises, higher requirements are posed on battery safety management;

3) What matters most to BMS are active cell balancing and design of SOC estimation algorithm. The ligh-asset hardware design companies will enjoy higher profitability;

4) Vehicle makers and battery cell vendors have their plans to extend into BMS industry chain. Due to technical barriers and constraint of R&D investments, it is hard for upstream and downstream enterprises to carry extension ambition. So, it is a rational act to outsource BMS solutions.

As far as competitive landscape is concerned, Chinese BMS market accommodates three kinds of enterprises:

1) Third-party BMS vendors, like E-power Electronics, Shenzhen Klclear Technology, SINOEV Technologies, Inc., Hunan Gold Cup New Energy Development, etc., of which E-power electronics is an early entrant whose BMS products are supplied to EV models of Changan Automobile, Dongfeng Motor, BAIC Motor, FOTON, JAC, ZOTYE, etc. This kind of vendors account for 42% of the overall market;

2) Battery module and PACK packaging companies, like Guoxuan Hi-Tech, CATL, OptimumNano, Sunwoda, etc. access into the market through either independent R&D or cooperation. This kind of companies makes up 37% of the overall market;

3) Vehicle makers. BYD and BAIC BJEV have made perfect deployments. BYD integrates battery, BMS and development of electric vehicle and enjoys advantages in cost and efficiency; BAIC BJEV is capable of developing BMS after acquisition of Atieva and need BMS suppliers no more. This kind of vendors share 21% of the overall market.

The report covers the following:

EV market development in China and the world (profile, market size, vehicle output, sales volume, etc.); EV market development in China and the world (profile, market size, vehicle output, sales volume, etc.);

Development of global BMS industry (status quo, forecast, market size, technology trends, etc.); Development of global BMS industry (status quo, forecast, market size, technology trends, etc.);

Development of BMS industry in China (status quo, forecast, price & cost, market size, competitive pattern, supply relation, technology trends, etc.); Development of BMS industry in China (status quo, forecast, price & cost, market size, competitive pattern, supply relation, technology trends, etc.);

World’s major BMS companies (companies’ and subsidiaries’ revenue, revenue structure, net income, R&D, products, supply to vehicle makers, developments, business in China, etc.); World’s major BMS companies (companies’ and subsidiaries’ revenue, revenue structure, net income, R&D, products, supply to vehicle makers, developments, business in China, etc.);

Leading BMS companies in China, involving independent third-party, battery cell manufacturers, and automakers (OEM) (companies’ and subsidiaries’ revenue, revenue structure, net income, R&D, products, supply to vehicle makers, latest projects, etc.); Leading BMS companies in China, involving independent third-party, battery cell manufacturers, and automakers (OEM) (companies’ and subsidiaries’ revenue, revenue structure, net income, R&D, products, supply to vehicle makers, latest projects, etc.);

Key players in BMS chip industry (revenue, revenue structure, net income, BMS chip solutions, etc.) Key players in BMS chip industry (revenue, revenue structure, net income, BMS chip solutions, etc.)

第一章 BMS电池管理系统概述

1.1 动力电池系统定义

1.2 电池管理系统定义

1.2.1 BMS定义

1.2.2 BMS分类和技术特性

1.2.3 BMS核心功能

第二章 BMS电池管理系统政策

2.1 新能源汽车产业政策

2.1.1 购置税减免政策

2.1.2 购置环节财政补贴政策

2.1.3 使用环节财政补贴政策

2.2 电池产业政策

2.2.1 《汽车动力蓄电池行业规范条件》

2.2.2 《新能源汽车生产企业及产品准入管理规则》

2.2.3 动力电池国标(GB/T)

2.2.4 动力电池回收国标(GB/T)

2.2.5 促进动力电池产业发展

2.2.6 动力电池补贴方案

2.3 制定中政策

2.3.1 电池管理系统(BMS)国标

2.4充电桩建设情况

第三章 全球BMS市场发展概况

3.1 全球电动车市场

3.2 市场规模和发展趋势

3.3 技术趋势

3.4 供应配套

第四章 中国BMS市场发展概况

4.1中国电动汽车市场

4.2 价格成本

4.3 市场规模

4.4 竞争格局

4.5 供应配套关系

4.6 技术路线

4.7 发展趋势

第五章 全球BMS厂商研究

5.1 Denso(Japan)

5.1.1 企业简介

5.1.2 BMS业务

5.2 Calsonic Kansei(Japan)

5.2.1 企业简介

5.2.2 BMS业务

5.3 Hitachi Automotive Systems (Japan)

5.3.1 企业简介

5.3.2 BMS业务

5.4 Mitsubishi Electric (Japan)

5.4.1 企业简介

5.4.2 BMS业务

5.5 Hyundai Kefico(Korea)

5.5.1 企业简介

5.5.2 BMS业务

5.6 LG Chem(Korea)

5.6.1 企业简介

5.6.2 BMS业务

5.7 SK Innovation (Korea)

5.7.1 企业简介

5.7.2 BMS业务

5.8 Tesla Motors (USA)

5.8.1企业简介

5.8.2 BMS业务

5.9 Lithium Balance (Denmark)

5.9.1 企业简介

5.9.2 BMS产品

5.9.3 BMS应用

5.9.4 在华布局

5.10 Vecture (Canada)

5.10.1 企业简介

5.10.2 BMS产品

5.10.3 BMS应用

5.10.4 产业布局

5.11 Rimac Automobili(Croatia)

5.11.1 企业简介

5.11.2 BMS产品

5.11.3 BMS应用

5.12 创扬科技股份有限公司(台湾)

5.12.1 企业简介

5.12.2 BMS业务

5.13 Clayton Power (Denmark)

5.13.1 企业简介

5.13.2 BMS业务

第六章 中国BMS厂商(独立第三方)

6.1 惠州亿能

6.1.1 企业简介

6.1.2 BMS业务

6.2 科列技术

6.2.1 企业简介

6.2.2 BMS业务

6.3 华霆动力

6.3.1 企业简介

6.3.2 BMS产品

6.4 均胜汽车电子(德国普瑞Preh)

6.4.1 企业简介

6.4.2 BMS业务

6.5 哈尔滨冠拓电源

6.5.1 企业简介

6.5.2 BMS产品

6.6 安徽力高

6.6.1 企业简介

6.6.2 BMS业务

6.7 宁波拜特

6.7.1 企业简介

6.7.2 BMS业务

6.8 宁波远道

6.8.1 企业简介

6.8.2 BMS产品

6.9 深圳市安泰佳科技

6.9.1 企业简介

6.9.2 BMS产品

6.10 芜湖天元

6.10.1 企业简介

6.10.2 BMS产品

6.11 深圳市派司德

6.11.1 企业简介

6.11.2 BMS业务

第七章 中国BMS厂商(整车类)

7.1 比亚迪(BYD)

7.1.1 企业简介

7.1.2 BMS业务

7.2 北汽新能源

7.2.1 企业简介

7.2.2 BMS业务

7.3 杭州杰能

7.3.1 企业简介

7.3.2 BMS业务

第八章 中国BMS厂商(动力电池类)

8.1 北京普莱德

8.1.1 企业简介

8.2 ATL

8.2.1 企业简介

8.2.2 BMS业务

8.3 国轩高科

8.3.1 企业简介

8.3.2 BMS业务

8.4 中航锂电

8.4.1 企业简介

8.4.2 BMS业务

8.5 欣旺达

8.5.1 企业简介

8.5.2 BMS业务

8.6 温斯顿电池

8.6.1 企业简介

8.6.2 BMS产品

第九章 全球BMS芯片厂商

9.1 Analog Devices(USA)

9.1.1 企业简介

9.1.2 经营情况

9.1.3 营收构成分析

9.1.4 毛利率分析

9.1.5 BMS解决方案

9.2 Texas Instruments (USA)

9.2.1 企业简介

9.2.2 经营情况

9.2.3 营收构成分析

9.2.4 毛利率分析

9.2.5 BMS芯片业务现状及展望

9.3 Infineon (Germany)

9.3.1 企业简介

9.3.2 经营情况

9.3.3 营收构成分析

9.3.4 毛利率分析

9.3.5 BMS芯片业务现状及展望

1. Overview of BMS

1.1 Definition of Power Battery

1.2 Definition of BMS

1.2.1 Definition

1.2.2 Classification and Technical Features

1.2.3 Core Functions

2. Policies on BMS

2.1 New Energy Vehicle Industry Policy

2.1.1 Purchase Tax Reduction & Exemption Policy

2.1.2 Fiscal Subsidies for Purchase

2.1.3 Fiscal Subsidies for Use

2.2 Battery Industry Policy

2.2.1 Standard Conditions for Automotive Power Battery Industry

2.2.2 Regulations on New Energy Vehicle Manufacturers and Products Access

2.2.3 National Standards for Power Battery (GB/T)

2.2.4 National Standards for Recycling of Power Battery (GB/T)

2.2.5 Promoting Development of Power Battery Industry

2.2.6 Subsidy Plan for Power Battery

2.3 Policies Being Made

2.3.1 National Standards for BMS

2.4 Charging Pile Construction

3. Global BMS Market

3.1 Global EV Market

3.2 Market Size and Development Trends

3.3 Technology Trends

3.4 Supporting

4. Chinese BMS Market

4.1 Chinese EV Market

4.2 Price & Cost

4.3 Market Size

4.4 Competitive Landscape

4.5 Supporting

4.6 Technology Roadmap

4.7 Development Trends

5. Global BMS Vendors

5.1 Denso (Japan)

5.1.1 Profile

5.1.2 BMS Business

5.2 Calsonic Kansei (Japan)

5.2.1 Profile

5.2.2 BMS Business

5.3 Hitachi Automotive Systems (Japan)

5.3.1 Profile

5.3.2 BMS Business

5.4 Mitsubishi Electric (Japan)

5.4.1 Profile

5.4.2 BMS Business

5.5 Hyundai Kefico(Korea)

5.5.1 Profile

5.5.2 BMS Business

5.6 LG Chem (Korea)

5.6.1 Profile

5.6.2 BMS Business

5.7 SK Innovation (Korea)

5.7.1 Profile

5.7.2 BMS Business

5.8 Tesla Motors (USA)

5.8.1 Profile

5.8.2 BMS Business

5.9 Lithium Balance (Denmark)

5.9.1 Profile

5.9.2 BMS Products

5.9.3 BMS Application

5.9.4 Presence in China

5.10 Vecture (Canada)

5.10.1 Profile

5.10.2 BMS Products

5.10.3 Application of BMS Products

5.10.4 Industrial Layout

5.11 Rimac Automobili(Croatia)

5.11.1 Profile

5.11.2 BMS Products

5.11.3 BMS Application

5.12 Digi-Triumph Technology (Taiwan)

5.12.1 Profile

5.12.2 BMS Business

5.13 Clayton Power (Denmark)

5.13.1 Profile

5.13.2 BMS Business

6. Chinese BMS Vendors (Independent Third Parties)

6.1 Huizhou E-power Electronics

6.1.1 Profile

6.1.2 BMS Business

6.2 Shenzhen Klclear Technology

6.2.1 Profile

6.2.2 BMS Business

6.3 SINOEV (Hefei) Technologies

6.3.1 Profile

6.3.2 BMS Products

6.4 Ningbo Joyson Electronic Corp. (German Preh GmbH)

6.4.1 Profile

6.4.2 BMS Business

6.5 Harbin Guantuo Power Equipment Co., Ltd.

6.5.1 Profile

6.5.2 BMS Products

6.6 Anhui LIGOO New Energy Technology Co., Ltd.

6.6.1 Profile

6.6.2 BMS Business

6.7 Ningbo Bate Technology Co., Ltd.

6.7.1 Profile

6.7.2 BMS Business

6.8 Ningbo Longway Electrical Co., Ltd.

6.8.1 Profile

6.8.2 BMS Products

6.9 Shenzhen Antega Technology Co., Ltd.

6.9.1 Profile

6.9.2 BMS Products

6.10 Wuhu Tianyuan Automobile Electric Co., Ltd.

6.10.1 Profile

6.10.2 BMS Products

6.11 Shenzhen Battsister Tech. Co., Ltd.

6.11.1 Profile

6.11.2 BMS Business

7. Chinese BMS Vendors (OEMs)

7.1 BYD

7.1.1 Profile

7.1.2 BMS Business

7.2 BAIC BJEV

7.2.1 Profile

7.2.2 BMS Business

7.3 Hangzhou Genwell-Power Co., Ltd.

7.3.1 Profile

7.3.2 BMS Business

8. Chinese BMS Vendors (Power Battery)

8.1 Beijing Pride New Energy Battery Technology Co., Ltd.

8.1.1 Profile

8.2 ATL

8.2.1 Profile

8.2.2 BMS Business

8.3 Hefei Guoxuan High-tech Power Energy Co., Ltd.

8.3.1 Profile

8.3.2 BMS Business

8.4 China Aviation Lithium Battery Co., Ltd.

8.4.1 Profile

8.4.2 BMS Business

8.5 Sunwoda Electronic Co., Ltd.

8.5.1 Profile

8.5.2 BMS Business

8.6 Winston Battery

8.6.1 Profile

8.6.2 BMS Products

9. Global BMS Chip Vendors

9.1 Analog Devices (USA)

9.1.1 Profile

9.1.2 Operation

9.1.3 Revenue Structure

9.1.4 Gross Margin

9.1.5 BMS Solutions

9.2 Texas Instruments (USA)

9.2.1 Profile

9.2.2 Operation

9.2.3 Revenue Structure

9.2.4 Gross Margin

9.2.5 Status Quo and Prospects of BMS Chip Business

9.3 Infineon (Germany)

9.3.1 Profile

9.3.2 Operation

9.3.3 Revenue Structure

9.3.4 Gross Margin

9.3.5 Status Quo and Prospects of BMS Chip Business

图:动力电池系统

图:中国动力电池系统全生产环节成本分解

图:电池系统中BMS成本占比

图:典型电池厂商的动力电池包系统

图:电池管理系统的硬件系统示意图

表:BMS系统四大模块构成和功能

图:工信部前九批免购置税目录车型统计

表:2009-2012年十米以上城市公交客车示范推广补助标准(单位:万元/辆)

表:2009-2012年公共服务用乘用车和轻型商用车示范推广补助标准(单位:万元/辆)

表:2013-2015年中国电动客车补贴标准

表:2016年中国纯电动乘用车、插电式混合动力(含增程式)乘用车补助标准

表:2016年中国纯电动、插电式混合动力等客车补助标准

表:2016年中国燃料电池汽车推广应用补助标准

表:中国新能源汽车纯电动续驶里程要求

表:2017年中国新能源客车补贴标准

表:2017年中国新能源乘用车补贴标准

表:2017年中国新能源货车和专用车补贴标准

表:2017年中国燃料电池汽车推广应用补贴标准

表:2013-2019年新能源乘用车中央财政补贴

表:2013-2019年新能源客车、货车中央财政补贴

表:节能与新能源公交车运营补助标准(2015-2019年)

表:符合《汽车动力蓄电池行业规范条件》企业目录(第一批)

表:符合《汽车动力蓄电池行业规范条件》企业目录(第二批)

表:符合《汽车动力蓄电池行业规范条件》企业目录(第三批)

表:符合《汽车动力蓄电池行业规范条件》企业目录(第四批)

图:中国已形成完善的电动汽车标准体系

表:2015年新发布的动力电池国标

表:GB/T 31467动力电池系统标准

图:电池系统测试通用流程(CARTAC)

表:2014-2016年全球电动乘用车销量对比(主要国家)

表:2015-2016年全球前20大电动乘用车销量对比

图:2014-2017全球新能源车(EV&PHEV)月度销量

图:2011-2020年全球电动乘用车(EV&PHEV)销量

图:全球69款外资主流新能源汽车(EV&PHEV)动力电池供应供应商

图:2014-2025全球电池管理系统(BMS)行业规模趋势

图:2013~2019年全球车用BMS分类产值预估

表:主动均衡和被动均衡技术解析

表:全球BMS主动均衡和被动均衡技术成本、应用分析

表:全球主流车企采用的BMS管理构架

图:全球主要新能源汽车对应的BMS与电池供应商

图:2010-2018年中国汽车保有量与产销量

图:2010-2017上半年中国电动汽车产量

图:2016-2017上半年中国电动汽车(分乘用车、商用车)月度产量

图:2011-2020年中国电动乘用车(EV&PHEV)产量

图:2011-2020年中国电动客车(EV&PHEV)产量

图:2013-2020年中国纯电动货车/物流车(EV)产量

表:乘用车/商用车BMS售价在动力电池价格中所占比例

图:2013-2020年中国BMS市场规模(分乘用车、客车、物流车)趋势

表:2020年中国新能源汽车BMS分产品市场规模

图:国内BMS市场竞争格局

表:国内主要BMS公司汇总

表:2015年中国新能源汽车BMS厂商市场份额

表:2016年中国新能源汽车BMS厂商市场份额

表:2017年上半年中国主流59款新能源乘用车BMS供应商

表:2015年中国纯电动乘用车BMS供应商(分厂商类型)市场份额

表:2016年中国纯电动乘用车BMS供应商(分厂商类型)市场份额

表:国内外主流BMS供应商的技术参数对比

图:主动均衡和被动均衡技术对比

表:国内主要BMS厂均衡技术情况

表:2016电动汽车电池管理系统BMS专利排行榜(分企业)

图:FY2016-FY2017 Denso汽车业务销售构成

图:FY2012-FY2017Denso动力总成设备部门销售情况

图:FY2016Denso分客户销售构成

图:FY2017Denso分客户销售构成

图:FY2012-FY2017 Denso研发投入情况

表: Denso电池管理系统配套车型

图:2010-2016财年Calsonic营业收入和近利润

图:2016财年Calsonic分地区营收情况

表:2012-2015年Calsonic Kansei电池管理系统配套车型

图:Hitachi Automotive Systems中度油电混合汽车用48V锂离子电池组

表:Hitachi Automotive Systems中度油电混合汽车用48V锂离子电池组的规格

图:FY2017三菱电机分业务销售情况

图:2010-2016年Kefico营业收入和净利润

图: LG化学股权结构图

图:2007-2016年LGC经营业绩

图:2015年LGC营业收入分区域

图:2016年LGC营业收入分产品

图:LG化学动力电池业务框架

图:LG化学BMS

图:2010-2015年LG化学动力电池及BMS应用现状

表:SKI动力锂电池及BMS技术参数

图:2011-2016年Tesla动力系统及相关组件业务营收情况

图:smart fortwo电动车

图:丰田RAV4 EV

图:可扩展电池管理系统(s-BMS)

图:集成电池管理系统(i-BMS)

图:英国Tennant 500ZE

图:TMHE电动叉车

图:ECOTRUCK7500型电动垃圾收集卡车

图:锂平衡客户

表:锂平衡中国地区代理商概况

图:Vecture公司的BMS

图:Vecture公司的BMS发展规划

图:Vecture公司的BMS产品参数

图:Vecture产品的应用领域

图:社区智能电网项目

图:“夏娃”项目

图:Rimac 的R-BMS2

图:Rimac Concept_One

图:创扬科技BMS产品应用领域

表:创扬科技BMS产品

表:创扬科技主要合作伙伴

图:Clayton BMS

图:2011-2016年亿能电子营业收入及净利润

表:亿能电子BMS产品

图:亿能电子部分合作伙伴

图:2012-2016科列技术经营业绩

表:2015-2016年科列技术BMS分应用类型营收

图:纯电动客车BMS

表:科列技术BMS模块功能

图:科列技术部分合作伙伴

表:科列技术BMS产品与功能

表:科列技术BMS主动均衡技术

图:江淮IEV5的电池组合情况

表:母公司均胜电子事业部及产品情况

图:宝马i3电池管理系统

图:2005-2015年德国普瑞营业收入

表:德国普瑞全球分部情况

图:BF101型电池管理系统

图:防水系列(BC111/BS111/BS113/BS313)

表:冠拓电源BMS主要参数

图:力高技术部分客户

图:EK-FT-12商用车BMS(增强型)

图:力高技术轻型车用BMS(B3系列产品)

图:力高技术大中型车用BMS(B5系列产品)

图:力高技术矿用型车用BMS(B1系列产品)

图:拜特测控主要客户

图:上汽荣威750HEV电池管理系统

表:拜特测控BMS主要参数

图:宁波远道BMS- 200 LF

图:宁波远道BMS- 36 LF

图:24V100AH动力锂电池管理系统

图:芜湖天元BMS

表:芜湖天元BMS主要参数

图:BMS-108电动车辆电池管理系列

图:派司德合作伙伴

图:2011-2020年比亚迪电动汽车销量

图:比亚迪电池PACK和BMS的设计

图:比亚迪微电子BMS保护IC产品

图:BESK动力电池包架构

图:杰能动力ABM-BMS主动均衡BMS

图:2016年北京普莱德股权结构图

图:2011-2016年北京普莱德经营业绩

表:2015-2016年北京普莱德前五大客户营收构成

表:北京普莱德主要客户及合作领域

图:2008-2016年ATL营业收入

表:CATL电动大巴BMS产品参数

表:CATL电动乘用车BMS产品参数

表:CATL电能储能系统BMS产品参数

图:2009-2016年国轩高科经营业绩

图:国轩高科BMS

表:国轩高科研发体系

图:2016年中航锂电股权结构图

图:2010-2016年中航锂电经营业绩

图:2010-2016年欣旺达营收与净利润

图:2016年欣旺达(按产品)营收占比

表:欣旺达电池管理系统主要指标

图:GTBMS005A-MC 11彩屏BMS

表:全球主流BMS芯片厂商解决方案

图:2007-2016年ADI营业收入及毛利率

图:2007-2016年ADI净利润及净利润率

图:2010-2016年ADI(分地区)营业收入情况

图:2016ADI(分行业)营业收入情况

图:2008-2016年ADI毛利率增长情况

图:ADI公司HEV/ EV锂电池管理解决方案(≤150 V)

图:ADI公司HEV/ EV锂电池管理解决方案(≥300 V)

图:2007-2016年TI营业收入及毛利率

图:2007-2016年TI净利润及净利润率

图:2007-2016年TI(分产品)营业收入情况

图:2010-2016年TI(分地区)营业收入情况

图:2007-2016年TI毛利率增长情况

图:2007-2016年TI主要产品营业利润率

图:TI混合动力和纯电动汽车解决方案

图:TI电池管理系统解决方案

图:TI的电池管理系统

图:FY2009-FY2016IFX营业收入及毛利率

图:FY2009-FY2016IFX净利润及净利润率

图:FY2009-FY2016IFX(分部门)营业收入情况

图:FY2009-FY2016IFX(分地区)营业收入情况

图:FY2009-FY2016IFX毛利率增长情况

图:FY2009-FY2016IFX汽车电子部门营收情况

图:IFX汽车电子全球主要客户

图:IFX的BMS解决方案

图:FY2009-FY2016IFX中国市场营收情况

Power Battery System

Production Cost Breakdown of Power Battery System

BMS Cost Proportion of Battery System

Power Battery Pack System of Typical Battery Manufacturers

Hardware System Diagram of BMS

Four Modules and Functions of BMS

MIIT’s Catalogue for the First Nine Batches of Models Exempt from Purchase Tax

Subsidy Standards for 10m+ Urban Public Bus Demonstration Promotion, 2009-2012(RMB10,000)

Subsidy Standards for Demonstration Promotion of Passenger Vehicles for Public Services and Lightweight Commercial Vehicles, 2009-2012

Subsidy Standards for Electric Passenger Vehicle in China, 2013-2015

Subsidy Standards for Electric Bus in China, 2013-2015

Subsidy Standards for Electric Passenger Vehicle (BEV & PHEV) in China, 2016

Subsidy Standards for Electric Bus (BEV &PHEV) in China, 2016

Subsidy Standards for Full-cell Vehicle in China, 2016

Requirements for Battery Electric Driving Mileage of New Energy Vehicles in China

Subsidy Standards for New Energy Bus, 2017

Subsidy Standards for New Energy Passenger Vehicle in China, 2017

Subsidy Standards for New Energy Truck and Special Vehicle in China, 2017

Promotion & Application Subsidy Standards for Full-cell Vehicle in China, 2017

Central Subsidy Standards for Electric Passenger Vehicle in China, 2013-2019

Central Subsidy Standards for New Energy Bus and Truck in China, 2013-2019

Subsidy Standards for Energy-saving and New Energy Buses under Operation, 2015-2019

Companies Complying with "Standard Conditions of Automotive Power Battery Industry" (First Batch)

Companies Complying with "Standard Conditions of Automotive Power Battery Industry" (Second Batch)

Companies Complying with "Standard Conditions of Automotive Power Battery Industry" (Third Batch)

Companies Complying with "Standard Conditions of Automotive Power Battery Industry" (Fourth Batch)

China's Perfect Electric Vehicle Standard System

Newly Released National Standards on Power Battery, 2015

GB / T 31467 Power Battery System Standards

General Flow (CARTAC) for Battery System Test

Global Electric Passenger Car Sales Comparison (Major Countries or Regions), 2014-2016

Global TOP20 Eletric Passenger Cars by Sales Volume, 2015-2016

Global New Energy Vehicle (EV & PHEV) Monthly Sales Volume, 2014-2017

Global Electric Passenger Car (EV & PHEV) Sales Volume, 2011-2020E

Power Battery Suppliers of 69 Foreign Mainstream New Energy Vehicle (EV&PHEV) Models

Scale of Global BMS Industry, 2014-2025E

Global Automotive BMS Output Value by Type, 2013-2019E

Analysis of Active and Passive Equalization Technologies

Costs and Applications of Global BMS Active and Passive Balancing Technologies

BMS Management Frameworks Adopted by Global Mainstream Automobile Enterprises

Major Global BMS and Battery Suppliers for New Energy Vehicles

China's Vehicle Ownership, Output and Sales Volume, 2010- 2018E

China's Electric Vehicle Output, 2010-2017H1

Monthly Output of Electric Vehicles (Passenger Cars and Commercial Vehicles) in China, 2016-H1 2017

China’s Sales of Electric Vehicles (EV&PHEV), 2011-2020E

Output of Electric Bus (EV&PHEV) in China, 2011-2020E

Output of Battery Truck/Logistics Vehicle in China, 2013-2020E

Proportion of Passenger Vehicle/Commercial Vehicle BMS Price in Power Battery Price

China's BMS Market Size (by Passenger Car, Bus, Logistics Vehicle), 2013-2020E

China's New Energy Passenger Vehicle BMS Market Size by Product, 2020E

Competitive Landscape of China BMS Market

Main BMS Companies in China

Market Share of New Energy Vehicle BMS Manufacturers in China, 2015

Market Share of New Energy Vehicle BMS Manufacturers in China, 2016

BMS Suppliers of 59 Mainstream New Energy Passenger Vehicles in China, 2017H1

Market Share of Battery Electric Passenger Vehicle BMS Suppliers (by Type) in China, 2015

Market Share of Battery Electric Passenger Vehicle BMS Suppliers (by Type) in China, 2015

Technical Parameter Comparison between Mainstream Chinese and Foreign BMS Suppliers

Comparison between Active and Passive Balancing Technologies

Balancing Technologies of Main BMS Vendors in China

Ranking of Electric Vehicle BMS Patents (by Company), 2016

Sales Structure of Denso’s Automotive Business, FY2016-FY2017

Sales of Denso’s Powertrain Equipment Division, FY2012-FY2017

Denso’s Sales Structure by Client, FY2016

Denso’s Sales Structure by Client, FY2017

Denso’s R & D Investment, FY2012-FY2017

Vehicle Models Supported by Denso's BMS, 2013-2015

Calsonic’s Revenue and Net Income, FY2010-FY2016

Calsonic’s Revenue by Region, FY2016

Vehicle Models Supported by Calsonic Kansei's BMS, 2012-2015

48V Lithium-ion Battery Pack of Hitachi Automotive Systems for Mild Hybrid Vehicles

Specifications of 48V Lithium-ion Battery Pack for Mild Hybrid Vehicles

Revenue of Mitsubishi Electric by Business, FY2017

Kefico’s Revenue and Net Income, 2010-2016

Equity Structure of LG Chemical, 2015

LGC’s Operating Results, 2007-2016

LGC’s Revenue by Region, 2015

LGC’s Revenue by Product, 2016

Power Battery Business Framework of LG Chemical

BMS of LG Chemical

Power Batteries and BMS Application of LG Chemical, 2010-2015

Power Lithium Batteries and BMS Technical Parameters of SKI

Tesla’s Revenue from Power System and Related Components, 2011-2016

Smart fortwo Electric Vehicles

Toyota’s RAV4 EV

Scalable BMS (s-BMS)

Integrated BMS (i-BMS)

British Tennant 500ZE

TMHE Electric Forklifts

ECOTRUCK7500 Electric Garbage Collection Trucks

Customers of Lithium Balance

Overview of Lithium Balance’s Agents in China

Vecture's BMS

Vecture’s Development Planning for BMS

Parameters of Vecture’s BMS

Application of Vecture's Products

Community Smart Grid Projects

‘Eve’ Project

Rimac’s R-BMS2

Rimac’s Concept_One

Application of Digi-Triumph’s BMS Products

Digi-Triumph’s BMS Products

Digi-Triumph’s Main Co-partners

Clayton BMS

Revenue and Net Income of Epower Electronics, 2011-2016

BMS Products of Epower Electronics

Some Partners of Epower Electronics

Operating Results of Klclear Technology, 2012-2016

BMS Revenue of Klclear Technology by Application, 2015-2016

Battery Electric Bus BMS

BMS Function Modules of Klclear Technology

Some Partners of Klclear Technology

BMS Products and Functions of Klclear Technology

BMS Active Equalization Technology of Klclear Technology

Battery Assembly of JAC iEV5

Electronics Division and Products of Joyson Electronics

BMW’s i3BMS

Preh’s Revenue, 2005-2015

Preh’s Global Divisions

BF101 BMS

Waterproof Series (BC111/BS111/BS113/BS313)

Main Parameters of Guantuo Power’s BMS

Some Customers of LIGOO New Energy Technology

EK-FT-12 Commercial Vehicle BMS (Enhanced)

LIGOO BMS (B3 Series) for Light Vehicle

LIGOO BMS (B5 Series) for Medium and Large Vehicle

LIGOO BMS (B1 Series) for Mine Vehicle

Major Customers of Ningbo Bate Technology

BMS of SAIC Roewe 750HEV

Main Parameters of Ningbo Bate Technology’s BMS

BMS- 200 LF of Ningbo Longway Electrical

BMS- 36 LF of Ningbo Longway Electrical

24V100AH Power Lithium BMS

BMS of Wuhu Tianyuan

Main Parameters of Wuhu Tianyuan’s BMS

BMS-108 Electric Vehicle Battery Management Series

Battsister’s Co-partners

BYD’s EV Sales Volume, 2011-2020E

Design of BYD’s Battery PACK and BMS

BMS Protection IC of BYD Microelectronics

Architecture of BESK’s Power Battery Pack

ABM-BMS Active Balanced BMS of Hangzhou Genwell-Power

Equity Structure of Beijing Pride New Energy Battery Technology, 2016

Operation Results of Beijing Pride New Energy Battery Technology, 2011-2016

Revenue Contribution of Beijing Pride New Energy Battery Technology’s Top 5 Cleints, 2015-2016

Customers and Cooperation Areas of Beijing Pride New Energy Battery Technology

ATL’s Operating Results, 2008-2016

BMS Product Parameter of CATL’s Electric Bus

BMS Product Parameter of CATL’s Electric Passenger Car

BMS Product Parameter of CATL’s Power Storage System

Business Performance of Hefei Guoxuan High-tech Power Energy, 2009-2016

Guoxuan’s High-tech BMS

R&D System of Guoxuan High-tech

Equity Structure of China Aviation Lithium Battery, 2016

Business Performance of China Aviation Lithium Battery, 2010-2016

Revenue and Net Income of Sunwoda Electronic, 2010-2016

Revenue Structure of Sunwoda Electronic by Product, 2016

Major Indicators of Sunwoda Electronic’s BMS

GTBMS005A-MC 11 Color-screen BMS

Solutions of Major Global BMS Chip Vendors

ADI’s Revenue and Gross Margin, 2007-2016

ADI’s Net Income and Net Profit Margin, 2007-2016

ADI’s Revenue (by Product), 2007-2014

ADI’s Revenue (by Region), 2010-2016

ADI’s Revenue (by Industry), 2016

ADI’s Gross Margin Growth, 2008-2016

ADI’s HEV/ EV Lithium Battery Management Solutions (≤150 V)

ADI’s HEV/ EV Lithium Battery Management Solutions (≥300 V)

TI’s Revenue and Gross Margin, 2007-2016

TI’s Net Income and Net Profit Margin, 2007-2016

TI’s Revenue (by Product), 2007-2016

TI’s Revenue (by Region), 2010-2016

TI’s Gross Margin Growth, 2007-2016

Operating Margin of TI’s Main Products, 2007-2016

TI’s Hybrid and Battery Electric Vehicle Solutions

TI’s BMS Solutions

TI’s BMS

IFX’s Revenue and Gross Margin, FY2009-FY2016

IFX’s Net Income and Net Profit Margin, FY2009-FY2016

IFX’s Revenue (by Division), FY2009-FY2016

IFX’s Revenue (by Region), FY2009-FY2016

IFX’s Gross Margin Growth, FY2009-FY2016

Revenue of IFX’s Automotive Electronics Division, FY2009-FY2016

Major Clients of IFX’s Automotive Electronics Division

IFX’s BMS Solutions

IFX’s Revenue in China, FY2009-FY2016

如果这份报告不能满足您的要求,我们还可以为您定制报告,请 留言说明您的详细需求。

|