|

|

|

报告导航:研究报告—

制造业—化工

|

|

2017-2021年全球及中国超高分子量聚乙烯行业研究报告 |

|

字数:2.6万 |

页数:106 |

图表数:139 |

|

中文电子版:10000元 |

中文纸版:5000元 |

中文(电子+纸)版:10500元 |

|

英文电子版:2600美元 |

英文纸版:2800美元 |

英文(电子+纸)版:2900美元 |

|

编号:CYH068

|

发布日期:2017-10 |

附件:下载 |

|

|

|

超高分子量聚乙烯(UHMWPE)是相对分子量150万以上的线性聚乙烯产品,一种具有优异综合性能的热塑性工程塑料,可通过加工形成各类板材、管材、纤维、薄膜等制品主要应用于军事如防弹衣、防弹头盔、防弹装甲、防割手套以及航空航天、航海装备、轨道交通、医用支架以及锂电池隔膜等高端领域。

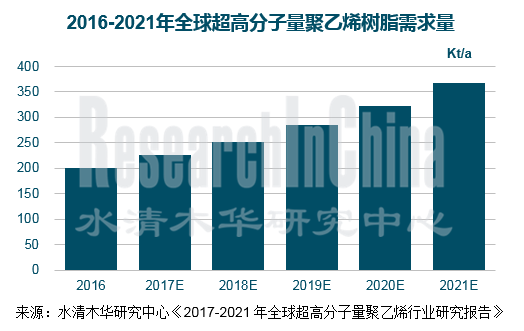

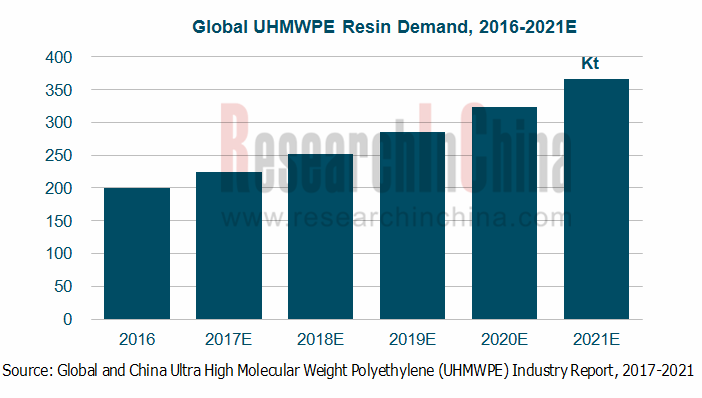

2016年,全球UHMWPE树脂产能和需求量分别达22.1万吨和20万吨,随着制造业对材料的特性要求越来越高,UHMWPE树脂以其优异的特性,有着较为广阔的市场前景,预计至2021年其产量和需求量分别有望达38万吨和36.7万吨。

超高分子量聚乙烯纤维即由超高分子量聚乙烯为原材料所纺出的纤维是重要的战略物资和高技术材料,是当前全球三大高性能纤维之一,市场处于供不应求状态。2016年,全球需求量约6万吨,产量仅3万吨左右。且随着军品、民品如各类高强轻质缆绳等领域不断开发,未来五年需求量有望保持15%左右增速增长,预计至2021年达到10.87万吨,且仍将处于供不应求状态。

同时,中国市场供需矛盾也较为突出,2016年中国超高分子量聚乙烯纤维需求量约2.0万吨,产量约9000吨,发展态势平稳。但受限于中国纺丝级专用树脂生产技术欠缺,纺丝技术及生产设备水平较发达国家略差,中国本土企业产品主要以中低端产品为主,高端产品主要被荷兰DSM、美国霍尼韦尔与日本三井化学等具备核心技术外资企业所垄断。其中DSM是目前全球产量最高、产品质量最佳的厂商,产量约占全球市场的80%。

超高分子量聚乙烯树脂企业方面,全球超高分子量聚乙烯树脂主要德国塞拉尼(CELANESE)、Braskem、荷兰DSM和日本三井化学等国外企业所占据,其中塞拉尼斯是全球超高分子量聚乙烯产品产能最高,在德国的欧伯豪森、美国德克萨斯州的毕肖普以及南京都设立了生产基地,合计总产能已达到约10.8万吨/年。其次为Braskem,产能约4.5万吨/年。

中国本土厂商主要有河南沃森、上海联乐化工、特佳劲、九江中科鑫星、齐鲁石化等少数几家企业合计产能约8万吨/年(含塞拉尼斯南京工厂),市场集中度较高,但受技术限制,产品以中低端产品为主。近几年,在超高分子量聚乙烯树脂下游需求增长拉动下,各大企业不断扩充产能,抢占市场份额,其中九江中科鑫星新材料有限公司在建6万吨/年超高分子量聚乙烯树脂项目,南京金陵塑胶化工有限公司10000吨年超高分子量聚乙烯项目等。

预计未来几年,超高分子量聚乙烯市场将迎来高速发展期,新企业的建成投产和现有企业产能扩大将同时进行,高性能化、低成本化及专用树脂化将是未来超高分子量聚乙烯树脂主要发展趋势,中国生产企业想要争取更大的份额,除价格因素,提升产品质量首当其冲。

水清木华研究中心《2017-2021年全球及中国超高分子量聚乙烯行业研究报告》着重研究了以下内容:

全球与中国超高分子量聚乙烯树脂市场供需、价格、竞争格局及发展趋势等; 全球与中国超高分子量聚乙烯树脂市场供需、价格、竞争格局及发展趋势等;

全球及中国超高分子量聚乙烯纤维市场发展现状、需求情况、竞争格局以及发展趋势等; 全球及中国超高分子量聚乙烯纤维市场发展现状、需求情况、竞争格局以及发展趋势等;

超高分子量聚乙烯板材、管材以及超高分子量聚乙烯锂电池隔膜市场发展情况; 超高分子量聚乙烯板材、管材以及超高分子量聚乙烯锂电池隔膜市场发展情况;

全球及中国13家超高分子量聚乙烯树脂重点企业经营情况及发展战略等; 全球及中国13家超高分子量聚乙烯树脂重点企业经营情况及发展战略等;

全球及中国13家超高分子量聚乙烯纤维重点企业经营情况及发展战略等。 全球及中国13家超高分子量聚乙烯纤维重点企业经营情况及发展战略等。

Ultra High Molecular Weight Polyethylene (UHMWPE), a kind of linear polyethylene with relative molecular weight of above 1.5 million and an engineering thermoplastic with excellent comprehensive properties, can be processed into products like sheets, pipes, fibers and films. It is primarily used in high-end fields, such as body armor, bulletproof helmet, bulletproof armor, anti-cutting gloves and aerospace, marine equipment, rail transit, medical stents and lithium-battery separator.

Global UHMWPE resin capacity and demand were 221kt and 200kt in 2016, respectively. As manufacturing has increasingly higher requirements on material properties, UHMWPE resin enjoys broad market prospects because of its excellent properties, finding output and demand as estimated 380kt and 367kt in 2021 separately.

UHMWPE fiber, a fiber spun out of UHMWPE, is a key strategic and high-tech material and one of three high-performance fibers, and has been in a state of short supply. Global demand for UHMWPE fiber was about 60kt in 2016, compared with an output of only 30kt or so. As more military and civilian products (like high-strength light cables) are developed, the demand for UHMWPE fiber is expected to maintain a growth rate of around 15% over the next five years, reaching 108.7kt in 2021 but still in short supply.

Meanwhile, the demand far exceeds the supply in the Chinese market. About 20kt of UHMWPE fiber was needed in the country in 2016, while the output was roughly 9kt. Restricted by lack of production technologies for spinning-grade specialty resins and weaker spinning technology and outdated production facilities than that in the developed countries, local Chinese enterprises produce mainly mid and low-end products, while high-end ones are monopolized by foreign players with core technologies including Dutch DSM, U.S. Honeywell and Japanese Mitsui Chemicals. DSM produces the most in the world.

Major global UHMWPE resin makers include CELANESE, Braskem, DSM and Mitsui Chemicals. CELANESE has the world’s largest UHMWPE products capacity with production bases in Oberhausen (Germany), Bishop, Texas (U.S.) and Nanjing (China) with capacity totaling about 108kt/a, followed by Braskem with capacity of approximately 45kt/a.

Key local Chinese resin producers are Henan Wosen Ultra-high Chemical Industry Science and Technology, Shanghai Lianle Chemical Industry Science and Technology, Anhui Tejiajin Fine Chemicals, Jiujiang Zhongke Xinxing New Materials and Sinopec Qilu Petrochemical Company with a combined capacity of about 80kt/a (including Celanese’s Nanjing-based plant), indicating a highly concentrated market but mainly for mid and low-end products due to technological limitations. Driven by rapid growth in demand from the downstream sectors of UHMWPE resin in recent years, companies have kept expanding capacity to scramble for market share. Jiujiang Zhongke Xinxing New Materials is building 60kt/a UHMWPE resin project, and Nanjing Jinling Plastic & Petrochemical is constructing 10kt/a UHMWPE project.

The UHMWPE market is expected to grow rapidly over the next couple of years with completion and operation of new enterprises and capacity expansion of existing companies going simultaneously. High-performance, low-cost and special-purpose will be main trends of UHMWPE resin. If Chinese producers wish to grab a larger market share, they must improve the quality of products, beside price factor.

Global and China Ultra High Molecular Weight Polyethylene (UHMWPE) Industry Report, 2017-2021 highlights the followings:

Global and Chinese UHMWPE resin market (supply & demand, price, competitive landscape, development trends, etc.); Global and Chinese UHMWPE resin market (supply & demand, price, competitive landscape, development trends, etc.);

Global and Chinese UHMWPE fiber market (status quo, demand, competitive landscape, development trends, etc.); Global and Chinese UHMWPE fiber market (status quo, demand, competitive landscape, development trends, etc.);

UHMWPE sheet, pipe, and lithium-battery separator markets; UHMWPE sheet, pipe, and lithium-battery separator markets;

12 major global and Chinese UHMWPE resin enterprises (operation, development strategies, etc.); 12 major global and Chinese UHMWPE resin enterprises (operation, development strategies, etc.);

13 major global and Chinese UHMWPE fiber enterprises (operation, development strategies, etc.). 13 major global and Chinese UHMWPE fiber enterprises (operation, development strategies, etc.).

第一章 概述

1.1 定义

1.2 制备工艺

1.3 产业链

1.4 发展历程

第二章 超高分子量聚乙烯树脂市场

2.1 全球市场

2.1.1 供给

2.1.2 需求

2.2 中国市场

2.2.1 发展现状

2.2.2 需求

2.3 价格

2.4 竞争格局

2.4.1 市场份额

2.4.2 产能

2.5 发展趋势

第三章 超高分子量聚乙烯纤维市场

3.1 概述

3.2 全球市场

3.2.1 市场现状

3.2.2 需求

3.3 中国市场

3.3.1 发展现状

3.3.2 政策

3.3.3 需求

3.4 企业格局

3.5 发展趋势

第四章 其他超高分子量聚乙烯制品市场

4.1 超高分子量聚乙烯板材

4.1.1 发展现状

4.1.2 企业格局

4.2 超高分子量聚乙烯管材

4.2.1 发展现状

4.2.2 企业格局

4.3 超高分子量聚乙烯锂电隔膜

4.3.1 锂电池隔膜市场

4.3.2 超高分子量聚乙烯锂电池隔膜市场

第五章 超高分子量聚乙烯树脂重点企业

5.1 Celanese

5.1.1 企业简介

5.1.2 经营情况

5.1.3 超高分子量聚乙烯业务

5.1.4 在华发展

5.2 Braskem

5.2.1 企业简介

5.2.2 经营情况

5.2.3 超高分子量聚乙烯业务

5.3 DSM

5.3.1 企业简介

5.3.2 经营情况

5.3.3 超高分子量聚乙烯业务

5.3.4 在华发展

5.4 日本三井化学

5.4.1 企业简介

5.4.2 经营情况

5.4.3 高分子量聚乙烯业务

5.4.4 在华发展

5.5 旭化成工业

5.5.1 企业简介

5.5.2 经营情况

5.5.3 超高分子量聚乙烯业务

5.5.4 在华发展

5.6 上海化工研究院

5.6.1 企业简介

5.6.2 经营情况

5.6.3 超高分子量聚乙烯业务

5.7 上海联乐化工科技有限公司

5.8 河南沃森超高化工科技有限公司

5.9 中国石化齐鲁石油化工公司

5.10 九江中科鑫星新材料有限公司

5.12 无锡市富坤化工有限公司

5.13 安徽省特佳劲精细化工有限公司

第六章 超高分子量聚乙烯纤维主要企业

6.1 日本东洋纺(Toyobo)公司

6.1.1 企业简介

6.1.2 经营情况

6.1.3 超高分子量聚乙烯纤维业务

6.1.4 在华发展

6.2 美国霍尼韦尔公司

6.2.1 企业简介

6.2.2 经营情况

6.2.3 超高分子量聚乙烯纤维业务

6.2.3 在华发展

6.3 北京同益中特种纤维技术开发有限公司

6.3.1 企业简介

6.3.2 超高分子量聚乙烯纤维业务

6.4 必康股份

6.4.1 企业简介

6.4.2 经营情况

6.4.3 超高分子量聚乙烯纤维业务

6.5 湖南中泰

6.6 山东爱地

6.7 江苏中益

6.8 宁波大成

6.9 上海斯瑞

6.10 中石化仪征化纤

6.11 北京威亚高性能纤维有限公司

6.12 剑乔科技

6.13 浙江千禧龙

1. Overview

1.1 Definition

1.2 Preparation Technology

1.3 Industry Chain

1.4 Development Course

2. UHMWPE Resin Market

2.1 Global Market

2.1.1 Supply

2.1.2 Demand

2.2 Chinese Market

2.2.1 Status Quo

2.2.2 Demand

2.3 Price

2.4 Competitive Pattern

2.4.1 Market Share

2.4.2 Capacity

2.5 Development Trend

3. UHMWPE Fiber Market

3.1 Overview

3.2 Global Market

3.2.1 Status Quo

3.2.2 Demand

3.3 Chinese Market

3.3.1 Status Quo

3.3.2 Policy

3.3.3 Demand

3.4 Corporate Pattern

3.5 Development Trend

4. Other UHMWPE Products Market

4.1 UHMWPE Sheets

4.1.1 Status Quo

4.1.2 Corporate Pattern

4.2 UHMWPE Pipes

4.2.1 Status Quo

4.2.2 Corporate Pattern

4.3 UHMWPE Lithium Battery Separator

4.3.1 Lithium Battery Separator Market

4.3.2 UHMWPE Lithium Battery Separator Market

5. UHMWPE Resin Companies

5.1 Celanese

5.1.1 Profile

5.1.2 Operation

5.1.3 UHMWPE Business

5.1.4 Development in China

5.2 Braskem

5.2.1 Profile

5.2.2 Operation

5.2.3 UHMWPE Business

5.3 DSM

5.3.1 Profile

5.3.2 Operation

5.3.3 UHMWPE Business

5.3.4 Development in China

5.4 Mitsui Chemicals

5.4.1 Profile

5.4.2 Operation

5.4.3 UHMWPE Business

5.4.4 Development in China

5.5 Asahi Kasei

5.5.1 Profile

5.5.2 Operation

5.5.3 UHMWPE Business

5.5.4 Development in China

5.6 Shanghai Research Institute of Chemical Industry

5.6.1 Profile

5.6.2 Operation

5.6.3 UHMWPE Business

5.7 Shanghai Lianle Chemical Industry Science and Technology Co., Ltd.

5.8 Henan Wosen Ultra-high Chemical Industry Science and Technology Co., Ltd.

5.9 Sinopec Qilu Petrochemical Company

5.10 Jiujiang Zhongke Xinxing New Materials Co., Ltd.

5.11 Wuxi Fukun Chemical Co., Ltd.

5.12 Anhui Tejiajin Fine Chemicals Co., Ltd.

6. UHMWPE Fiber Companies

6.1 Toyobo

6.1.1 Profile

6.1.2 Operation

6.1.3 UHMWPE Fiber Business

6.1.4 Development in China

6.2 Honeywell

6.2.1 Profile

6.2.2 Operation

6.2.3 UHMWPE Fiber Business

6.2.4 Development in China

6.3 Beijing Tongyizhong Specialty Fiber Technology & Development Co., Ltd.

6.3.1 Profile

6.3.2 UHMWPE Fiber Business

6.4 Jiangsu Bicon Pharmaceutical Listed Company

6.4.1 Profile

6.4.2 Operation

6.4.3 UHMWPE Fiber Business

6.5 Jiangsu Bicon Pharmaceutical Listed Company

6.6 Shandong ICD High Performance Fibre Co., Ltd.

6.7 Jiangsu Zhongyi Special Fiber Co., Ltd.

6.8 Ningbo Dacheng New Materials Co., Ltd.

6.9 Shanghai SURREY Technology Co., Ltd.

6.10 Sinopec Yizheng Chemical Fibre Co., Ltd.

6.11 Beijing Winyarn High Performance Fiber Co., Ltd.

6.12 Jian Qiao Technology Co., Ltd.

6.13 Zhejiang Qianxilong Special Fiber Co., Ltd.

图:超高分子量聚乙烯分子结构

表:UHMWPE综合性能

图:超高分子量聚乙烯主要优异性能

表:超高分子量聚乙烯合成方法

图:超高分子量聚乙烯产业链

图:超高分子量聚乙烯主要应用领域

图:超高分子量聚乙烯产业发展历程

图:2016-2021年全球超高分子量聚乙烯树脂产能

图:2016-2021年全球超高分子量聚乙烯树脂需求量

表:中国超高分子量聚乙烯树脂发展历程

图:2016-2021年中国超高分子量聚乙烯树脂需求量

图:2016年中国UHMWPE树脂消费结构

表:2017年全球及中国主要企业超高分子量聚乙烯树脂价格

图:2017年中国超高分子量聚乙烯树脂企业市场份额(按产能)

表:2017年全球及中国主要超高分子量聚乙烯树脂生产商及产能

表:全球主要超高分子量聚乙烯生产商及超高分子量聚乙烯树脂品牌

图:超高分子量聚乙烯树脂发展趋势

图:2016-2021年全球及中国超高分子量聚乙烯树脂需求量

图:超高分子量聚乙烯纤维优异特性

图:干法路线合成超高分子量聚乙烯纤维

图:超高分子量聚乙烯纤维产业链

图:超高分子聚乙烯纤维专用树脂性能参数

图:2015-2021年全球超高分子量聚乙烯纤维产能

图:2015-2021年全球超高分子量聚乙烯纤维需求量

图:2016年欧美地区超高分子量聚乙烯纤维(分用途)需求结构

图:超高分子量聚乙烯纤维主要应用领域

图:超高分子量聚乙烯纤维应用于飞机雷达外罩

图:超高分子量聚乙烯纤维应用于飞行器结构及宇航服

图:超高分子量聚乙烯纤维应用于航海装备

图:超高分子量聚乙烯纤维应用于水路飞机装备

图:超高分子量聚乙烯纤维用于防切割手套

表:中国主要的超高分子量聚乙烯纤维相关政策

图:2015-2021年中国超高分子量聚乙烯纤维需求量

图:2016年中国超高分子量聚乙烯纤维(分用途)需求结构

表:2017年全球及中国主要超高分子量聚乙烯纤维企业及产能

表:中国超高分子量聚乙烯纤维发展趋势

图:化纤工业智能制造趋势

图:互联网+纺织信息化技术水平发展趋势

表:2017年中国主要超高分子量聚乙烯板材生产商及产能

表:UHMWPE管道性能

表: UHMWPE管道VS其他类管道性能

图:超高分子量聚乙烯管用于航道

图:超高分子量聚乙烯管用于市场工程

表:中国主要UHMWPE管道生产商及生产线数量

图:湿法PE隔膜显微图

图:2012-2022年全球(分产品)锂电隔膜出货量

图:2009-2016年中国锂电池隔膜产量

图:2014-2020年中国隔膜(分技术路线)产量,国内湿法隔膜产量增速高于干法隔膜

图:2015年全球与中国湿法隔膜市场占有率

图:2015年全球湿法隔膜企业市场份额

图:锂电池隔膜用超高分子量聚乙烯专用树脂

图:塞拉尼斯产品布局

图:塞拉尼斯工厂全球分布

图:2012-2017年Celanese公司营业收入与净利润

图:2017年季度Celanese公司销售额

表:2015-2017年Celanese公司(分业务)销售额及构成

表:2014-2016年Celanese公司(分地区)销售额及构成

表:Celanese 公司Advanced Engineered Materials部门主要产品

表:Celanese公司超高分子量聚乙烯业务工厂

表:2017年3月塞拉尼斯公司超高分子量聚乙烯产品价格上涨

表:塞拉尼斯超高分子量聚乙烯产品型号

图:2014-2016年Celanese在中国销售额及占比

图:Braskem公司简介

图:Braskem全球分布

表:2015-2016年Braskem公司主要经营数据

图:2002-2016年Braskem(分产品)产能

图:2016年Braskem Business Model

图:2016年Braskem公司(分业务)营业收入构成

图:2016年Braskem公司(分地区)营业收入构成

图:Braskem公司PE产品扩产情况

表:Braskem公司超高分子量聚乙烯产品主要牌号及性能

图:DSM发展历程

图:2016年DSM fact

图:2012-2017年DSM销售额与净利润

表:2015-2017H1年DSM(分业务)销售额

图:2015-2016年DSM(分终端市场)销售额构成

图:2016年DSM公司(分地区)销售额构成

图:2012-2016年DSM公司Material业务经营情况

图:DSM公司Material业务产品发展趋势

图:DSM公司 Dyneema产品简介

图: DSM公司 Dyneema产品产业链

图:DSM公司超高分子量聚乙烯相关产品主要下游市场

图:2016年DSM公司 Dyneema产品经营情况

图:2016年DSM公司 Dyneema产品(分地区)销售额

图:2016年DSM公司 Dyneema产品(分下游市场)销售额

图: DSM公司UHMWPE产品全球布局

图:2010-2017财年三井化学主要经营数据

表:2017财年一季度三井化学经营数据

表:2015-2017财年三井化学(分业务)销售额

表:2017财年一季度三井化学(分业务)销售额与营业利润

图:2012-2017财年三井化学(分地区)销售额构成

图:2014-2020财年三井化学中期计划

图:2025年三井化学业务发展目标

图:2017-2020财年三井化学投资计划

图:三井化学超高分子量聚乙烯主要用途

图:2012-2016财年三井化学在中国销售额及占比

图:三井化学在中国工厂分布

图:旭化成全球研发基地分布

表:2015-2017财年旭化成主要经营数据

表:2015-2017财年旭化成(分部门)销售额与营业利润

表:2017财年一季度旭化成(分业务)销售额与营业利润

图:2025年旭化成(分业务)销售额发展目标

表:2015-2016财年旭化成在华销售额及占比

图:旭化成在中国子公司分布

图:2012-2017年上海化工研究院营业收入与净利润

图:上海化工研究院超高分子量聚乙烯催化研发现状

表:联乐化工公司主要超高分子量聚乙烯产品型号及主要性能参数

表:齐鲁石化主要超高分子量聚乙烯产品品牌牌号及性能参数

表:2013-2016年特佳劲精细化工公司主要经营数据

表:2013-2017财年Toyobo公司经营数据

图:2013-2018财年Toyobo公司(分业务)销售额

图:2013-2017财年Toyobo公司(分业务)营业利润

图:2016财年东洋纺(分地区)销售额构成

表:东洋纺超高分子量聚乙烯纤维主要产品型号及性能

图:东洋纺超高分子量聚乙烯纤维性能

图:东洋纺超高分子量聚乙烯纤维主要用途

图:2010-2016年Honeywell净销售额及净利润

图:2016年Honeywell(分业务)净销售额及构成

图:2016年Honeywell公司(分地区)销售额构成

图:2016年Honeywell(分终端市场)销售额构成

Honeywell Businesses At A Glance

表:1994-2017年Honeywell公司在中国分业务发展历程

图:同益中超高分子量聚乙烯纤维产品发展历程

图:2014-2017年必康股份营业收入与净利润

图:2016-2017年必康股份(分业务)营业收入及构成

表:2016-2017年必康股份(分产品)营业收入及构成

表:2016-2017年必康股份(分地区)营业收入及构成

图:2016-2020年必康股份超高分子量聚乙烯纤维产能

图:湖南中泰主营业务分布

表:湖南中泰超高分子量聚乙烯纤维主要型号及参数

图:山东爱地超高分子量聚乙烯纤维发展历程

图:山东爱地主要超高分子量聚乙烯纤维产品型号

图:江苏中益超高分子量聚乙烯纤维布局及发展历程

图:宁波大成发展历程及主营业务

表:宁波大成公司超高分子量聚乙烯纤维主要产品型号及性能参数

图:上海斯瑞科技主营业务布局及发展历程

图:仪征化纤主营业务及发展历程

图:剑乔科技主营业务分布及发展历程

Molecular Structure of Ultra high Molecular Weight Polyethylene (UHMWPE)

Overall Properties of UHMWPE

Main Excellent Properties of UHMWPE

Synthesis Methods of UHMWPE

UHMWPE Industry Chain

Main Applications of UHMWPE

Development History of UHMWPE Industry

Global UHMWPE Resin Capacity, 2016-2021E

Global UHMWPE Resin Demand, 2016-2021E

Development History of UHMWPE Resin in China

UHMWPE Resin Demand in China, 2016-2021E

UHMWPE Resin Consumption Structure in China, 2016

Prices of Major Global and Chinese UHMWPE Resin Companies, 2017

Market Share of UHMWPE Resin Companies in China by Capacity, 2017

Major Global and Chinese UHMWPE Resin Producers and Their Capacity, 2017

Major Global UHMWPE Producers and Their UHMWPE Resin Brands

Development Trends of UHMWPE Resin

Global and Chinese UHMWPE Resin Demand, 2016-2021E

Excellent Properties of UHMWPE Fiber

UHMWPE Fiber Synthesized by Dry Process

UHMWPE Fiber Industry Chain

Performance Parameters of Resins for UHMWPE Fiber

Global UHMWPE Fiber Capacity, 2015-2021E

Global UHMWPE Fiber Demand, 2015-2021E

UHMWPE Fiber Demand Structure in European and American Region by Purpose, 2016

Main Applications of UHMWPE Fiber

UHMWPE Fiber Applied in Aircraft Radar Cover

UHMWPE Fiber Applied in Aircraft Structure and Space Suit

UHMWPE Fiber Applied in Nautical Equipment

UHMWPE Fiber Applied in Amphibious Aircraft Equipment

UHMWPE Fiber Applied in Anti-cutting Gloves

Policies Concerning UHMWPE Fiber in China

UHMWPE Fiber Demand in China, 2015-2021E

UHMWPE Fiber Demand Structure in China by Purpose, 2016

Major Global and Chinese UHMWPE Fiber Companies and Their Capacity, 2017

Development Trends of UHMWPE Fiber in China

Intelligent Manufacturing Trends of Chemical Fiber Industry

Development Trends of Internet+ Textile Information Technology

Major UHMWPE Sheet Manufacturers in China and Their Capacity, 2017

Performance of UHMWPE Pipeline

Comparison of Performance between UHMWPE Pipeline and Other Pipelines

UHMWPE Pipeline Applied in Channel

UHMWPE Pipeline Applied in Municipal Engineering

Major UHMWPE Pipeline Manufacturers in China and Their Number of Production Lines

Micrograph of Wet-process PE Separator

Global Lithium Battery Separator Shipments by Product, 2012-2022E

Lithium Battery Separator Output in China, 2009-2016

Separator Output in China by Technology Roadmap--Wet-process Separator Growing Faster than Dry-process Separator, 2014-2020E

Market Share of Wet-process Separator in Global and China Markets, 2015

Market Share of Global Wet-process Separator Companies, 2015

Techniques Process of International Lithium Battery Separator Manufacturers

Resins for UHMWPE Used in Lithium Battery Separator

Celanese’s Product Layout

Global Presence of Celanese’s Factories

Celanese’s Revenue and Net Income, 2012-2017

Celanese’s Quarterly Sales, 2017

Celanese’s Sales Structure by Business, 2015-2017

Celanese’s Sales Structure by Region, 2014-2016

Main Products of Celanese’s Advanced Engineered Materials Division

Celanese’s UHMWPE Factories

Celanese’s Increase in Price of UHMWPE Products, Mar 2017

Celanese’s UHMWPE Product Models

Celanese’s Sales in China and % of Total Revenue, 2014-2016

Braskem’s Profile

Braskem’s Global Presence

Braskem’s Operating Data, 2015-2016

Braskem’s Capacity by Product, 2002-2016

Braskem’s Business Model, 2016

Braskem’s Revenue Structure by Business, 2016

Braskem’s Revenue Structure by Region, 2016

Braskem’s PE Capacity Expansion

Main Brands and Performance of Braskem’s UHMWPE Products

DSM’s Development History

DSM’s Fact, 2016

DSM’s Sales and Net Income, 2012-2017

DSM’s Sales Breakdown by Business, 2015-2017H1

DSM’s Sales Structure by Terminal Market, 2015-2016

DSM’s Sales Structure by Region, 2016

Operation of DSM’s Material Business, 2012-2016

Product Development Trends of DSM’s Material Business

Overview of DSM’s Dyneema Products

Industry Chain of DSM’s Dyneema Products

Main Downstream Markets of DSM’s UHMWPE Products

Operation of DSM’s Dyneema Products, 2016

DSM’s Dyneema Product Sales by Region, 2016

DSM’s Dyneema Product Sales by Downstream Market, 2016

DSM’s Global Layout of UHMWPE Products

Mitsui Chemicals’ Operating Data, FY2010-FY2017

Mitsui Chemicals’ Operating Data, FY2017Q1

Mitsui Chemicals’ Sales Breakdown by Business, FY2015-FY2017

Mitsui Chemicals’ Sales Breakdown and Operating Income by Business, FY2017Q1

Mitsui Chemicals’ Sales Structure by Region, FY2012-FY2017

Mitsui Chemicals’ Medium-term Plan, FY2014-FY2020

Mitsui Chemicals’ Business Development Goals, 2025

Mitsui Chemicals’ Investment Plans, FY2017-FY2020

Main Purposes of Mitsui Chemicals’ UHMWPE

Mitsui Chemicals’ Sales in China and % of Total Revenue, FY2012-FY2016

Presence of Mitsui Chemicals’ Factories in China

Global Presence of Asahi Kasei’s R&D Bases

Asahi Kasei’s Operating Data, FY2015-FY2017

Asahi Kasei’s Sales Breakdown and Operating Income by Division, FY2015-FY2017

Asahi Kasei’s Sales Breakdown and Operating Income by Business, FY2017Q1

Asahi Kasei’s Sales Goals by Business, 2025

Asahi Kasei’s Sales in China and % of Total Revenue, FY2015-FY2016

Presence of Mitsui Chemicals’ Subsidiaries in China

Revenue and Net Income of Shanghai Research Institute of Chemical Industry, 2012-2017

UHMWPE Catalytic R&D Status of Shanghai Research Institute of Chemical Industry

Models and Performance Parameters of Shanghai Lianle Chemical Industry’s Main UHMWPE Products

Brands and Performance Parameters of Sinopec Qilu Petrochemical’s Main UHMWPE Products

Operating Data of Anhui Tejiajin Fine Chemicals, 2013-2016

Toyobo’s Operating Data, FY2013-FY2017

Toyobo’s Sales Breakdown by Business, FY2013-FY2018

Toyobo’s Operating Income by Business, FY2013-FY2017

Toyobo’s Sales Structure by Region, FY2016

Main Models and Performance of Toyobo’s UHMWPE Fiber Products

Performance of Toyobo’s UHMWPE Fiber

Main Purposes of Toyobo’s UHMWPE Fiber

Honeywell’s Net Sales and Net Income, 2010-2016

Honeywell’s Net Sales Structure by Business, 2016

Honeywell’s Sales Structure by Region, 2016

Honeywell’s Sales Structure by Terminal Market, 2016

Honeywell’s Businesses at a Glance

Honeywell’s Development History in China by Business, 1994-2017

Development History of Beijing Tongyizhong Specialty Fiber’s UHMWPE Fiber Products

Revenue and Net Income of Jiangsu Bicon Pharmaceutical, 2014-2017

Revenue Structure of Jiangsu Bicon Pharmaceutical by Business, 2016-2017

Revenue Structure of Jiangsu Bicon Pharmaceutical by Product, 2016-2017

Revenue Structure of Jiangsu Bicon Pharmaceutical by Region, 2016-2017

UHMWPE Fiber Capacity of Jiangsu Bicon Pharmaceutical, 2016-2020E

Operating Business Distribution of Hunan Zhongtai Special Equipment

Main Models and Parameters of Hunan Zhongtai Special Equipment’s UHMWPE Fiber

Development History of Shandong ICD High Performance Fibre’s UHMWPE Fiber

UHMWPE Fiber Product Models of Shandong ICD High Performance Fibre

Layout and Development History of Jiangsu Zhongyi Special Fiber’s UHMWPE Fiber

Development History and Operating Business of Ningbo Dacheng New Materials

Models and Performance Parameters of Ningbo Dacheng New Materials’ Main UHMWPE Fiber Products

Operating Business Layout and Development History of Shanghai SURREY Technology

Operating Business and Development History of Sinopec Yizheng Chemical Fibre

Operating Business Distribution and Development History of Jian Qiao Technology

如果这份报告不能满足您的要求,我们还可以为您定制报告,请 留言说明您的详细需求。

|